Premium Quality Plastic Coated Aluminum Tape for Durable and Versatile Applications , [Your Brand Name]

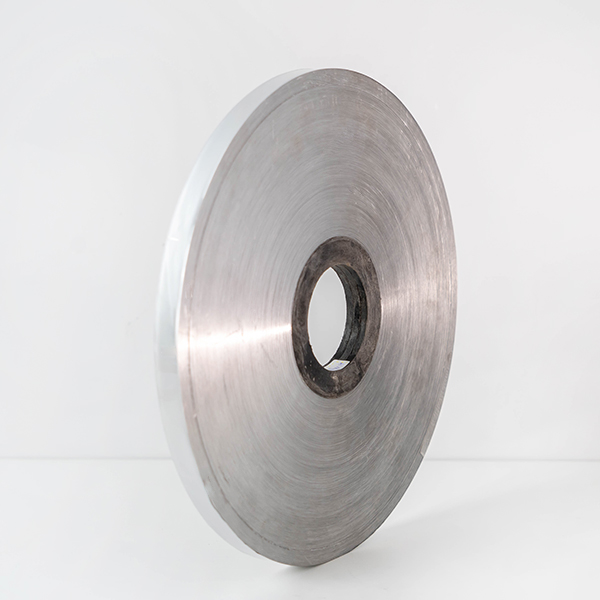

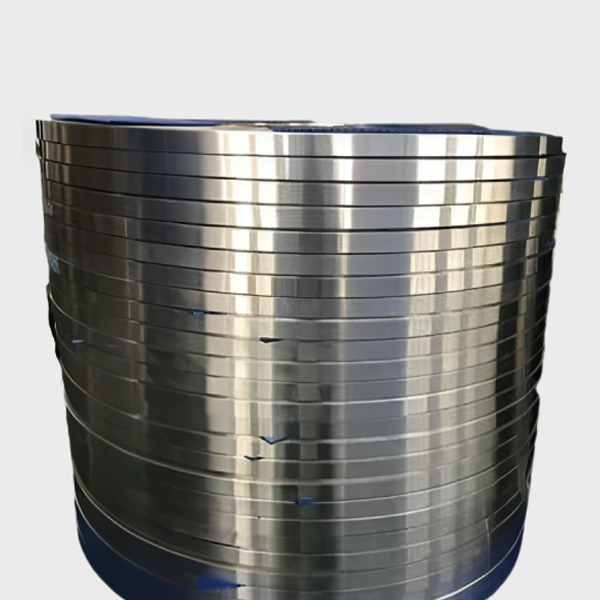

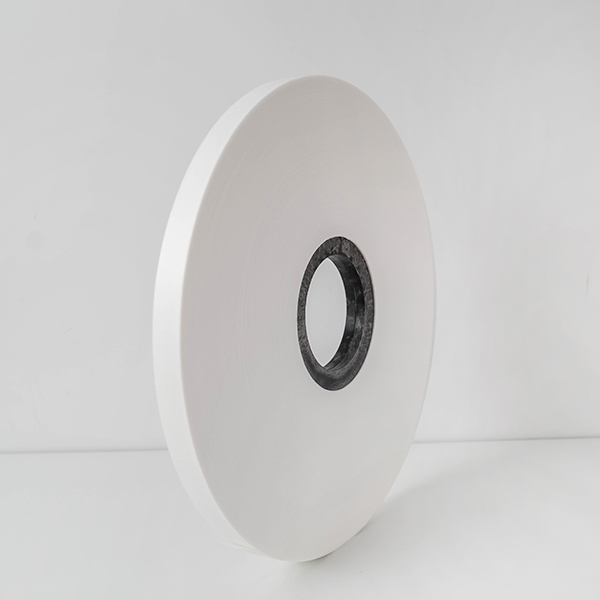

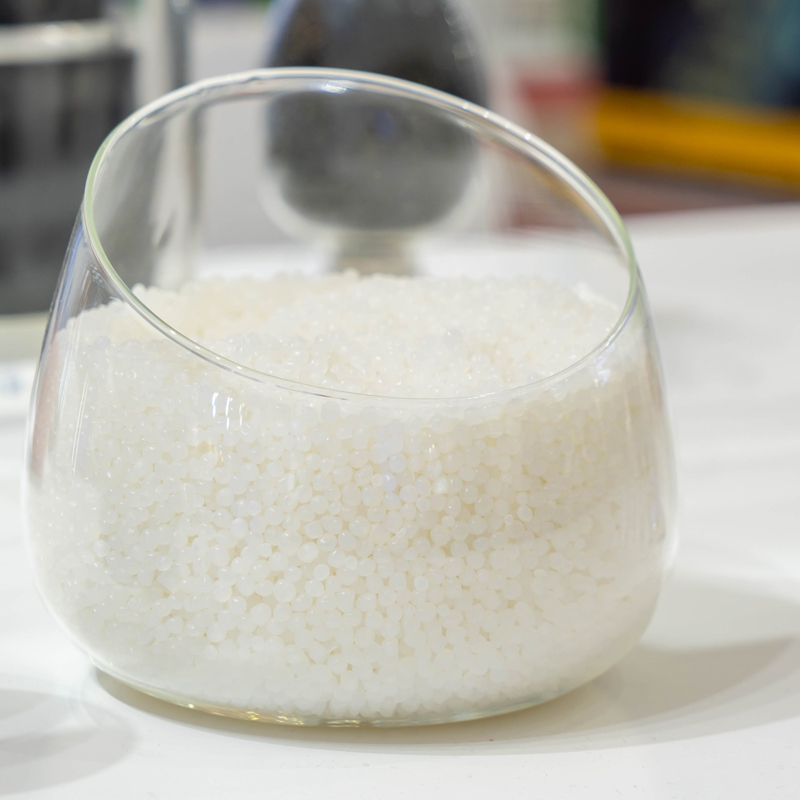

One World Cable Materials Co., Ltd., a leading manufacturer and supplier based in China, is proud to present our top-quality product, Plastic Coated Aluminum Tape. Designed specifically for use in various cables and wiring applications, our tape offers exceptional performance and durability. Our Plastic Coated Aluminum Tape is manufactured using premium-grade materials to ensure maximum reliability and longevity. The aluminum core provides excellent electrical conductivity, while the plastic coating offers superior protection against moisture, corrosion, and other external factors. This combination ensures optimal performance even in harsh environments. With our extensive expertise and advanced production facilities, we can customize the tape to meet specific customer requirements. Whether you need a particular thickness, width, or color, we can deliver tailor-made solutions that match your exact specifications. Our Plastic Coated Aluminum Tape is trusted by customers worldwide for its excellent quality and outstanding performance. It has found applications in various industries, including telecommunications, electrical, and automotive. With our commitment to excellence and customer satisfaction, we strive to provide the best products and services possible. Choose One World Cable Materials Co., Ltd. as your reliable partner for all your cable material needs. Contact us today to learn more about our Plastic Coated Aluminum Tape and how it can benefit your business.

Related Products