Products

Poly butylene Terephthalate (PBT)

Product Introduction

Poly butylene Terephthalate is milky white or milky yellow translucent to opaque thermoplastic polyester particles. Poly butylene Terephthalate (PBT) has excellent mechanical properties, electrical insulation properties, oil resistance, chemical corrosion resistance, easy moulding and low moisture absorption, etc., and is the most commonly used material for optical fiber secondary coating.

In the optical fiber cable, the optical fiber is very fragile. Although the mechanical strength of the optical fiber is improved after the primary coating, the requirements for cabling are still not enough, so the secondary coating is required. The secondary coating is the most important mechanical protection method for the optical fiber in the optical fiber cable manufacturing process, because secondary coating not only provides further mechanical protection against compression and tension, but also creates excess length of optical fiber. Due to its good physical and chemical properties, Poly butylene terephthalate is usually used as an extrusion material for the secondary coating of optical fibers in outdoor optical fiber cable.

We can provide OW-6013,OW-6015 and other types of Poly butylene Terephthalate material for secondary coating of optical fiber cable.

characteristics

The material PBT we provided has the following characteristics:

1) Good stability. Small shrinkage scale, small volume changing in using, good stability in forming.

2) High mechanical strength. Large modulus, good extension performance, high tensile strength. The anti-lateral pressure value of tube is higher than the standard.

3) High distortion temperature. Excellent distortion performance under large load and small load conditions.

4) Hydrolysis resistance. With excellent resistance to hydrolysis, making optical fiber cable more longer life than standard requirements.

5) Chemical resistance. Excellent chemical resistance and good compatibility with fiber paste and cable paste, not easy to be corroded.

Application

Mainly used for the secondary coating production of the optical fiber of the outdoor loose-tube optical fiber cable.

Technical Parameters

OW-PBT 6013

| No. | Testing Item | Unit | Standard Requirement | Value |

| 1 | Density | g/cm3 | 1.25~1.35 | 1.31 |

| 2 | Melt flow rate (250℃、2160g) | g/10min | 7.0~15.0 | 12.5 |

| 3 | Moisture content | % | ≤0.05 | 0.03 |

| 4 | Water absorption | % | ≤0.5 | 0.3 |

| 5 | Tensile strength at yield | MPa | ≥50 | 52.5 |

| Elongation at yield | % | 4.0~10.0 | 4.4 | |

| Breaking Elongation | % | ≥100 | 326.5 | |

| Tensile Modulus of elasticity | MPa | ≥2100 | 2241 | |

| 6 | Flexural Modulus | MPa | ≥2200 | 2243 |

| Flexural Strength | MPa | ≥60 | 76.1 | |

| 7 | Melting point | ℃ | 210~240 | 216 |

| 8 | Shore Hardness (HD) | / | ≥70 | 73 |

| 9 | Izod impact(23℃) | kJ/㎡ | ≥5.0 | 9.7 |

| Izod impact(-40℃) | kJ/㎡ | ≥4.0 | 7.7 | |

| 10 | Coefficient of Linear Expansion (23℃~80℃) | 10-4K-1 | ≤1.5 | 1.4 |

| 11 | Volume resistivity | Ω·cm | ≥1.0×1014 | 3.1×1016 |

| 12 | Heat distortion temperature (1.80MPa) | ℃ | ≥55 | 58 |

| Heat distortion temperature (0.45MPa) | ℃ | ≥170 | 178 | |

| 13 | Thermal hydrolysis | |||

| Tensile Strength at Yield | MPa | ≥50 | 51 | |

| Elongation at Break | % | ≥10 | 100 | |

| 14 | Compatibility between material and filling compounds | |||

| Tensile Strength at Yield | MPa | ≥50 | 51.8 | |

| Elongation at Break | % | ≥100 | 139.4 | |

| 15 | Loose tube anti side pressure | N | ≥800 | 825 |

| Note: This type of Poly butylene Terephthalate (PBT) is a general-purpose optical cable secondary coating material. | ||||

OW-PBT 6015

| No. | Testing Item | Unit | Standard Requirement | Value |

| 1 | Density | g/cm3 | 1.25~1.35 | 1.31 |

| 2 | Melt flow rate (250℃、2160g) | g/10min | 7.0~15.0 | 12.6 |

| 3 | Moisture content | % | ≤0.05 | 0.03 |

| 4 | Water absorption | % | ≤0.5 | 0.3 |

| 5 | Tensile strength at yield | MPa | ≥50 | 55.1 |

| Elongation at yield | % | 4.0~10.0 | 5.2 | |

| Elongation at break | % | ≥100 | 163 | |

| Tensile Modulus of elasticity | MPa | ≥2100 | 2316 | |

| 6 | Flexural Modulus | MPa | ≥2200 | 2311 |

| Flexural Strength | MPa | ≥60 | 76.7 | |

| 7 | Melting point | ℃ | 210~240 | 218 |

| 8 | Shore Hardness (HD) | / | ≥70 | 75 |

| 9 | Izod impact (23℃) | kJ/㎡ | ≥5.0 | 9.4 |

| Izod impact (-40℃) | kJ/㎡ | ≥4.0 | 7.6 | |

| 10 | Coefficient of Linear Expansion (23℃~80℃) | 10-4K-1 | ≤1.5 | 1.44 |

| 11 | Volume resistivity | Ω·cm | ≥1.0×1014 | 4.3×1016 |

| 12 | Heat distortion temperature (1.80MPa) | ℃ | ≥55 | 58 |

| Heat distortion temperature (0.45MPa) | ℃ | ≥170 | 174 | |

| 13 | Thermal hydrolysis | |||

| Tensile Strength at Yield | MPa | ≥50 | 54.8 | |

| Elongation at Break | % | ≥10 | 48 | |

| 14 | Compatibility between material and filling compounds | |||

| Tensile Strength at Yield | MPa | ≥50 | 54.7 | |

| Elongation at Break | % | ≥100 | 148 | |

| 15 | Loose tube anti side pressure | N | ≥800 | 983 |

| Note: This Poly butylene Terephthalate (PBT) has high pressure resistance, and is suitable for the production of secondary coating of air-blown micro-optical cable. | ||||

Packaging

Material PBT is packaged in 1000kg or 900kg polypropylene woven bag outer packing, lined with aluminum foil bag; or 25kg kraft paper bag outer packing, lined with aluminum foil bag.

After packaging, it is placed on a pallet.

1) 900kg ton bag size: 1.1m*1.1m*2.2m

2) 1000kg ton bag size: 1.1m*1.1m*2.3m

Storage

1) The product should be kept in a clean, hygienic, dry and ventilated storehouse.

2) The product should be kept away from chemicals and corrosive substances, should not be stacked together with flammable products and should not be close to fire sources.

3) The product should avoid direct sunlight and rain.

4) The product should be packed completely to avoid moisture and pollution.

5) The storage period of the product at ordinary temperature is 12 months from the date of production.

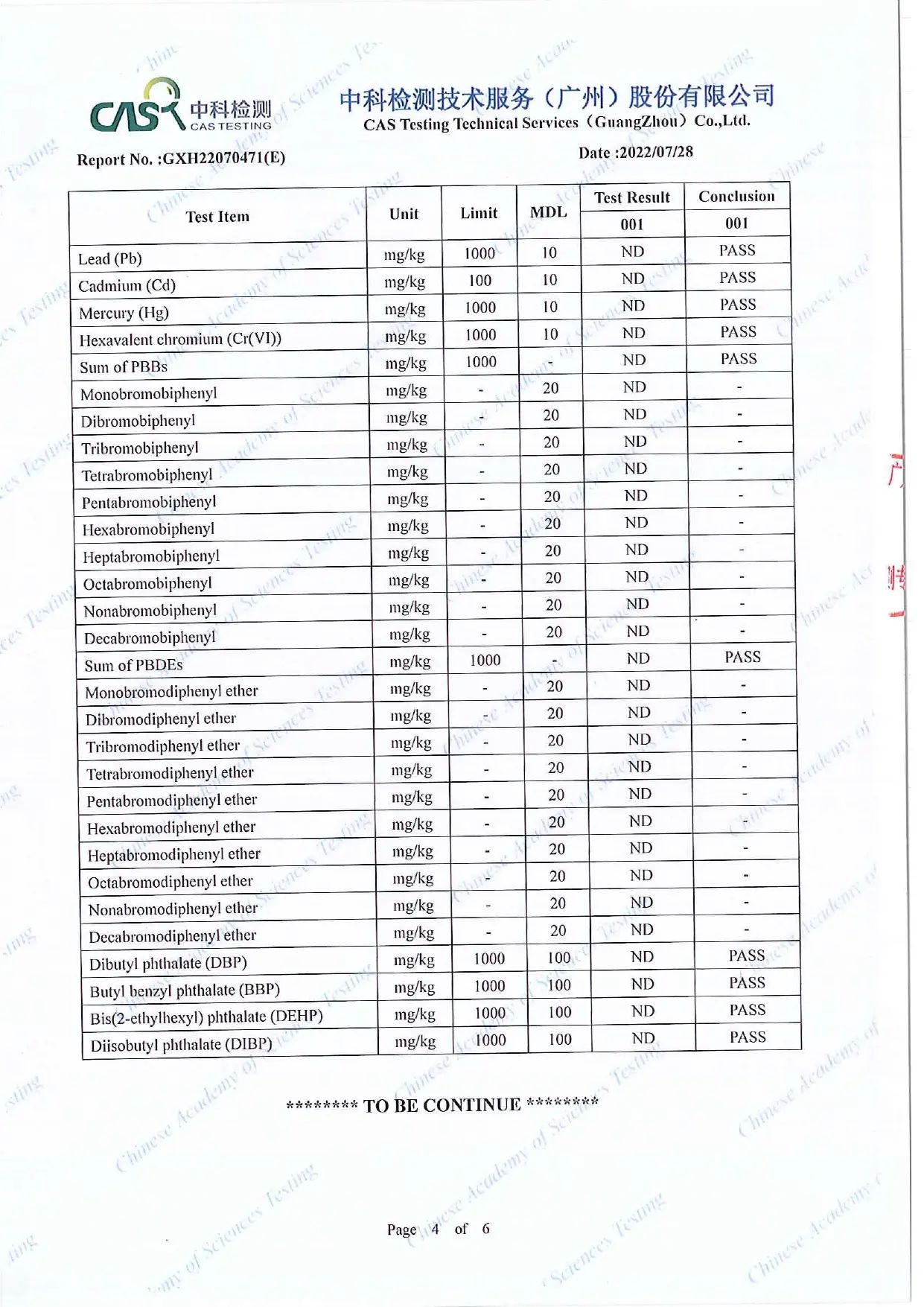

Certification

Feedback

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.