Topleveranciers van aramidegaren: vind hoogwaardige producten tegen concurrerende prijzen

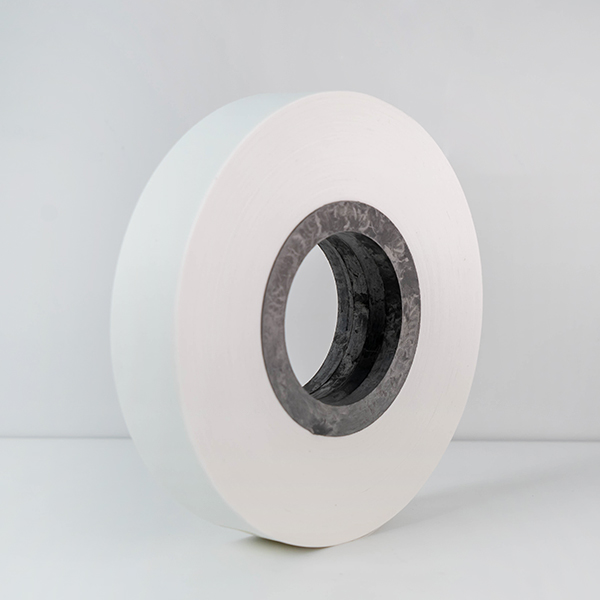

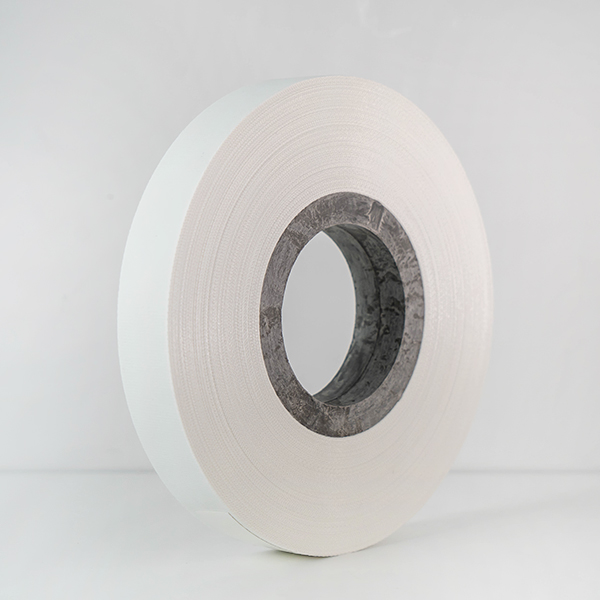

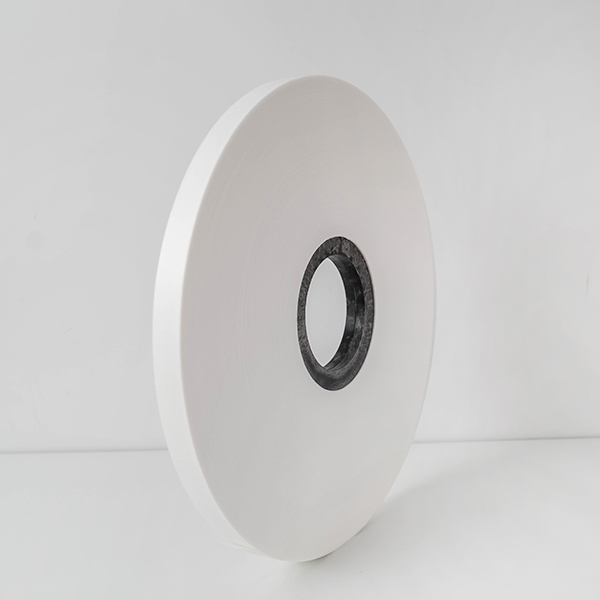

Maak kennis met ONE WORLD CABLE MATERIALS CO., LTD., een toonaangevende leverancier van aramidegaren gevestigd in China. Als gerenommeerde fabrikant en leverancier streven wij ernaar om hoogwaardige producten te leveren die voldoen aan uw behoeften op het gebied van kabelmateriaal. Ons aramidegaren is speciaal ontworpen en geproduceerd met behulp van geavanceerde technologie, wat zorgt voor uitzonderlijke kwaliteit en duurzaamheid. We zijn er trots op een uitgebreid assortiment aramidegaren aan te bieden, geschikt voor diverse toepassingen in de kabelindustrie. Met een toegewijd team van experts en ultramoderne faciliteiten kunnen we grote bestellingen verwerken en oplossingen op maat bieden die voldoen aan uw specifieke eisen. Onze strenge kwaliteitscontroles garanderen dat elk product dat ons bedrijf verlaat, voldoet aan de wereldwijde industrienormen. Als betrouwbare leverancier van aramidegaren geven we prioriteit aan klanttevredenheid en bieden we concurrerende prijzen, waardoor we een ideale keuze zijn voor bedrijven wereldwijd. Onze toewijding aan uitmuntendheid, snelle levering en ongeëvenaarde klantenservice heeft ons een sterke reputatie in de branche opgeleverd. ONE WORLD CABLE MATERIALS CO., LTD. is uw partner voor hoogwaardige aramidegarenproducten. Neem vandaag nog contact met ons op en ontdek ons assortiment. Ervaar zelf het verschil dat een samenwerking met een gerenommeerde en vertrouwde fabrikant en leverancier van aramidegaren met zich meebrengt.

Gerelateerde producten