Products

Fiber Reinforced Plastic (FRP GFRP) Rods

Product Introduction

Glass fiber reinforced plastic (GFRP) rods is a high performance composite material made of glass fibre as reinforcement and resin as base material, which is cured and pultruded at a specific temperature. Because of its very high tensile strength and elastic modulus, GFRP is widely used as a reinforcement in ADSS optical fiber cable, FTTH butterfly optical fiber cable and various layer-stranded outdoor optical fiber cable.

advantages

The use of GFRP as a reinforcement for optical fiber cable has the following advantages:

1) GFRP is all dielectric, which can avoid lightning strikes and strong electromagnetic field interference.

2) Compared with metal reinforcement, GFRP is compatible with other materials of optical fiber cable and will not produce harmful gas due to corrosion, which will lead to hydrogen loss and affect the transmission performance of optical fiber cable.

3) GFRP has the characteristics of high tensile strength and light weight, which can reduce the weight of optical cable and facilitate the manufacture, transportation and laying of optical cable.

Application

GFRP is mainly used for non-metallic reinforcement of ADSS optical fiber cable, FTTH butterfly optical fiber cable and various layer-stranded outdoor optical fiber cable.

Technical Parameters

Product Specifications

| Nominal Diameter (mm) | 0.4 | 0.5 | 0.9 | 1 | 1.2 | 1.3 | 1.4 | 1.5 | 1.6 | 1.7 |

| 1.8 | 2 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | |

| 2.9 | 3 | 3.1 | 3.2 | 3.3 | 3.5 | 3.7 | 4 | 4.5 | 5 | |

| Note: More specifications, please contact our sales staff. | ||||||||||

Technical Requirement

| Item | Technical Parameters | |

| Density (g/cm3) | 2.05~2.15 | |

| Tensile Strength (MPa) | ≥1100 | |

| Tensile modulus (GPa) | ≥50 | |

| Breaking Elongation (%) | ≤4 | |

| Bending strength (MPa) | ≥1100 | |

| Bending modulus of elasticity (GPa) | ≥50 | |

| Absorption (%) | ≤0.1 | |

| Min.instantaneous bend radius (25D, 20℃±5℃) | No burrs, no cracks, no bends, smooth to the touch, can be bounced straight | |

| High temperature bending performance (50D, 100℃±1℃, 120h) | No burrs, no cracks, no bends, smooth to the touch, can be bounced straight | |

| Low temperature bending performance (50D, -40℃±1℃, 120h) | No burrs, no cracks, no bends, smooth to the touch, can be bounced straight | |

| Torsional performance (±360°) | No disintegration | |

| Compatibility of the material with the filling mixture | Appearance | No burrs, no cracks, no bends, smooth to the touch |

| Tensile Strength (MPa) | ≥1100 | |

| Tensile modulus (GPa) | ≥50 | |

| Linear expansivity (1/℃) | ≤8×10-6 | |

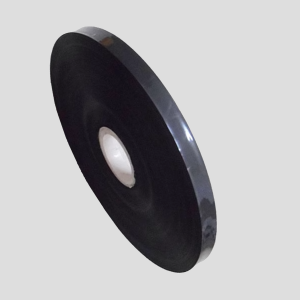

Packaging

GFRP is packed in plastic or wooden bobbins. Diameter (0.40 to 3.00) mm, standard delivery length ≥ 25km; diameter (3.10 to 5.00) mm, standard delivery length ≥ 15km; non-standard diameter and non-standard length can be produced according to customer requirements.

Storage

1) The product shall be kept in a clean, dry and ventilated warehouse.

2) The product should not be stacked together with flammable products and should not be close to fire sources.

3) The product should avoid direct sunlight and rain.

4) The product should be packed completely to avoid moisture and pollution.

5) The product shall be protected from heavy pressure and other mechanical damage during storage.

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.