Products

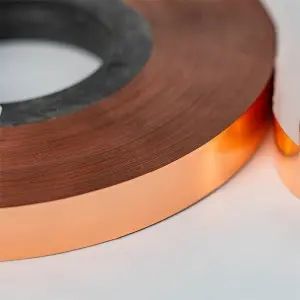

Copper Foil Mylar Tape

Product Introduction

Copper foil Mylar tape is a metal composite tape which is made of single-sided or double-sided copper foil as the base material, polyester film as the reinforcing material, bonded with polyurethane glue, cured at high temperature, and then slit. Mylar tape can provide high shielding coverage and is suitable for the overall shielding layer outside the cable core of control cable, signal cable. Other cable products that have higher requirements for shielding performance, and the outer conductor of coaxial cables.

Copper foils Mylar tape can make the signal transmitted in the cable better free from electromagnetic interference and reduce the signal attenuation during the data transmission process, so that the signal can be transmitted safely and effectively improve the electrical performance of the cable.

We can provide single-sided/ double-sided copper foil Mylar tape. The double-sided copper foil Mylar tape is composed of a layer of polyester film in the middle and a layer of copper foil on both side. The double-layer copper reflects and absorbs the signal twice, which has a better shielding effect.

The copper foil Mylar tape we provided has the characteristics of high tensile strength, good shielding performance, and high dielectric strength, etc. Compared with aluminum foil Mylar tape, it has better shielding performance.

Application

Mainly used as the overall shielding layer outside the cable core of control cable, signal cable and other cable products, and the outer conductor of coaxial cables.

Technical Parameters

Single-sided Copper Foils tape:

| Nominal Thickness (μm) | Composite Structure | Nominal Thickness of Copper Foil (μm) | Nominal Thickness of PET film (μm) | Tensile Strength(MPa) | Breaking Elongation (%) |

| 30 | Cu+Mylar | 15 | 12 | ≥110 | ≥12 |

| 33 | 18 | 12 | ≥110 | ≥12 | |

| 35 | 20 | 12 | ≥110 | ≥15 | |

| 41 | 15 | 23 | ≥120 | ≥15 | |

| 44 | 18 | 23 | ≥120 | ≥15 | |

| 46 | 20 | 23 | ≥120 | ≥15 | |

| 100 | 50 | 50 | ≥150 | ≥20 | |

| Note: More specifications, please contact our sales staff. | |||||

Double-sided Copper Foil Mylar tape:

| Nominal thickness (μm) |

Composite structure | Nominal thickness of A side copper foil(μm) | Nominal thickness of PET film (μm) | Nominal thickness of B side copper foil (μm) | Tensile strength (MPa) | Breaking Elongation (%) |

| 50 | Cu+Mylar+Cu | 15 | 12 | 15 | ≥110 | ≥10 |

| 60 | 15 | 23 | 15 | ≥120 | ≥10 | |

| Note: More specifications, please contact our sales staff. | ||||||

Packaging

Each pad of copper foil Mylar tape is individually placed in a moisture-proof film bag with desiccant, then vacuumize it, and finally put it into a carton.

Wooden box size: 1250*860*660 /1 ton

Storage

1) The Copper Foils tape shall be kept in a clean, dry and ventilated warehouse. The warehouse should be ventilated and cool, avoid direct sunlight, high temperature, heavy humidity, etc., to prevent products from swelling, oxidation and other problems.

2) The product should not be stacked together with flammable products and should not be close to fire sources.

3) The product should be packed completely to avoid moisture and pollution.

4) The product shall be protected from heavy pressure and other mechanical damage during storage.

5) The product cannot be stored in the open air, but a tarp must be used when it must be stored in the open air for a short time.

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.