The Advantages of Mica Tape for Electrical Insulation , Ultimate Guide

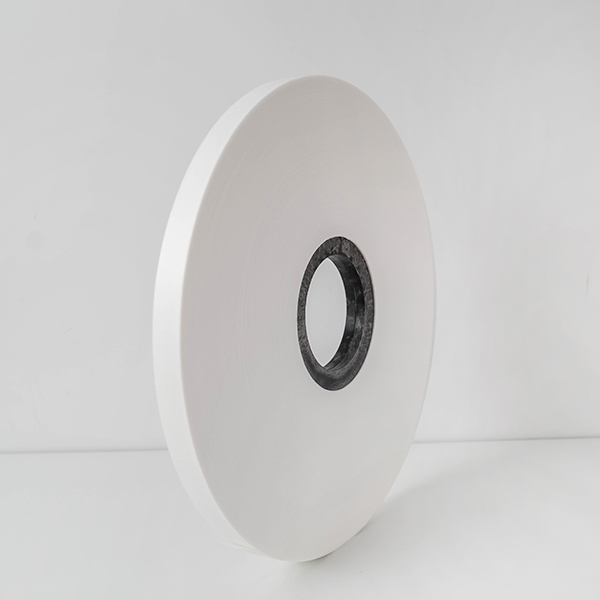

Introducing Mica Tape: The Reliable Cable Insulation Solution by ONE WORLD CABLE MATERIALS CO., LTD. ONE WORLD CABLE MATERIALS CO., LTD. takes immense pride in being a leading manufacturer and supplier of high-quality cable materials in China. Our commitment to excellence and innovation drives us to introduce our latest product, Mica Tape, designed to revolutionize cable insulation solutions. Mica Tape is a cutting-edge product meticulously engineered by our expert team to enhance the durability, safety, and performance of cables. Made from superior-quality mica sheets and with the use of advanced adhesive technology, our Mica Tape provides exceptional electrical insulation, heat resistance, and fireproof properties. It is specifically designed to withstand high temperatures, ensuring optimal cable performance even under extreme conditions. As a reputable manufacturer, we prioritize delivering products that meet global industry standards. Our Mica Tape is tested rigorously to ensure its compliance with various quality parameters. This guarantees that our customers receive a reliable and highly efficient cable insulation solution. ONE WORLD CABLE MATERIALS CO., LTD. aims to provide our valued clients with utmost satisfaction by offering top-notch products paired with exceptional customer service. With Mica Tape, we are revolutionizing the cable insulation industry, delivering reliability, safety, and performance in a single product. Choose ONE WORLD CABLE MATERIALS CO., LTD. for your cable material needs, and experience the excellence of our products and services firsthand. Contact us today to explore the vast range of reliable cable materials we offer.

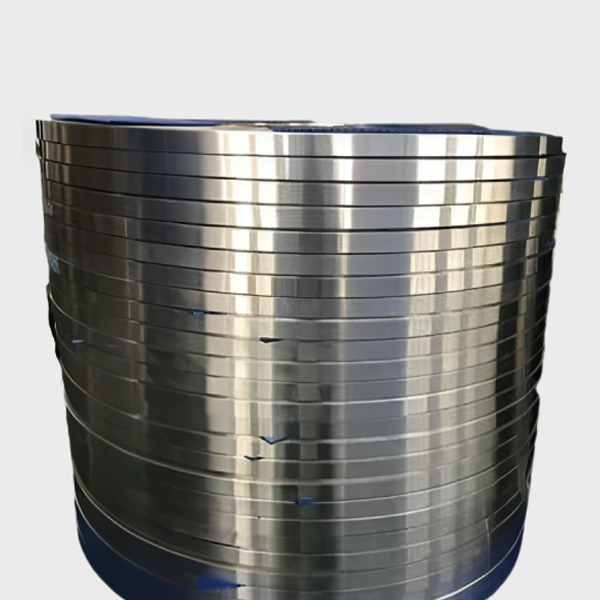

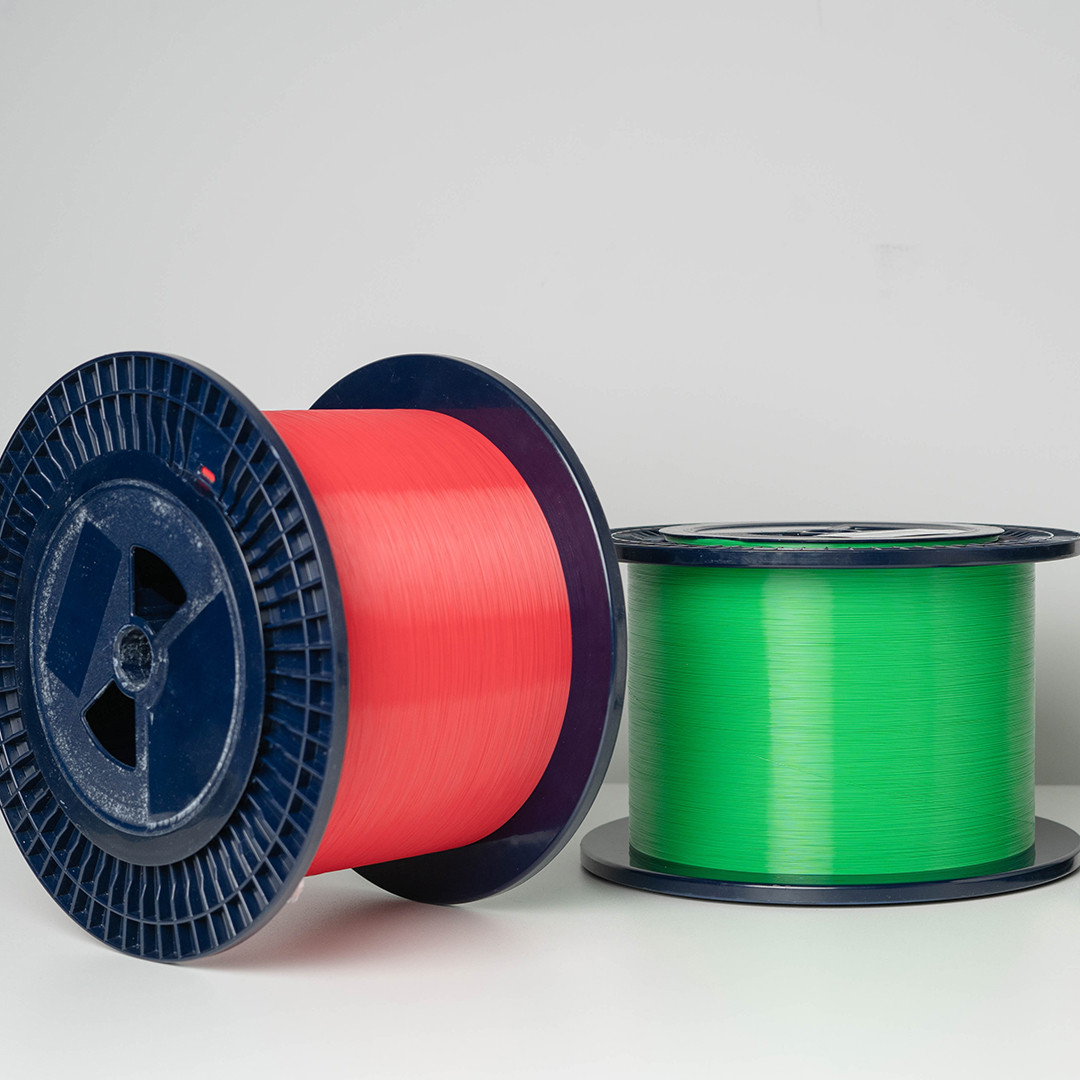

Related Products