Products

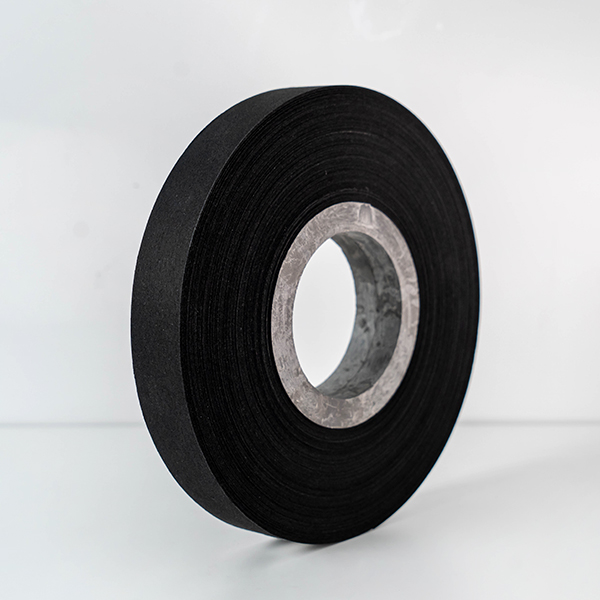

Semi-conductive Water Blocking Tape

Product Introduction

Semi-conductive water blocking tape (or water block tape) is a modern high-tech water-blocking material with semi-conductive water-absorbing and expansion function (swelling tape), which is composed of semi-conductive polyester fiber non-woven fabric and high-speed expansion water-absorbing resin.

Among them, the semi-conductive base layer is manufactured by evenly distributing the semi-conductive compound on the base cloth that is relatively flat, has strong temperature resistance and high strength; the semi-conductive water-blocking material uses powdery polymer water-absorbing material and conductive carbon black. The water-absorbing material is attached to the base fabric by padding or coating.

The semi-conductive water blocking tape has the function of water-absorbing and expansion and improving the electric field distribution in the cable, and is widely used in power cables of various voltage levels.

We can provide single-sided/double-sided semi-conductive water blocking tape. The single-sided semi-conductive water block tape is composed of a single layer of semi-conductive polyester fiber non-woven fabric and high-speed expansion water-absorbing resin; the double-sided semi-conductive water blocking tape is composed of semi-conductive polyester fiber non-woven fabric, high-speed expansion water-absorbing resin and semi-conductive polyester fiber non-woven fabric in turn. The single-sided semi-conductive water block tape has better water blocking performance because it has no base cloth to block.

characteristics

The semi-conductive water blocking tape we provided has the following characteristics:

1) The surface is flat, without wrinkles.

2) The fiber is evenly distributed, the water blocking powder and the base tape are firmly bonded, without delamination and powder removal.

3) High mechanical strength, easy for wrapping and longitudinal wrapping processing.

4) Strong hygroscopicity, high expansion height, fast expansion rate, and good gel stability.

5) Small surface resistance and volume resistivity, which can effectively weaken the electric field strength

6) Good heat resistance, high instantaneous temperature resistance, cable can maintain stable performance under instantaneous high temperature.

7) High chemical stability, no corrosive components, resistant to bacterial and fungal erosion.

Application

Mainly used in power cables of various voltage levels to block water and improve electric field distribution.

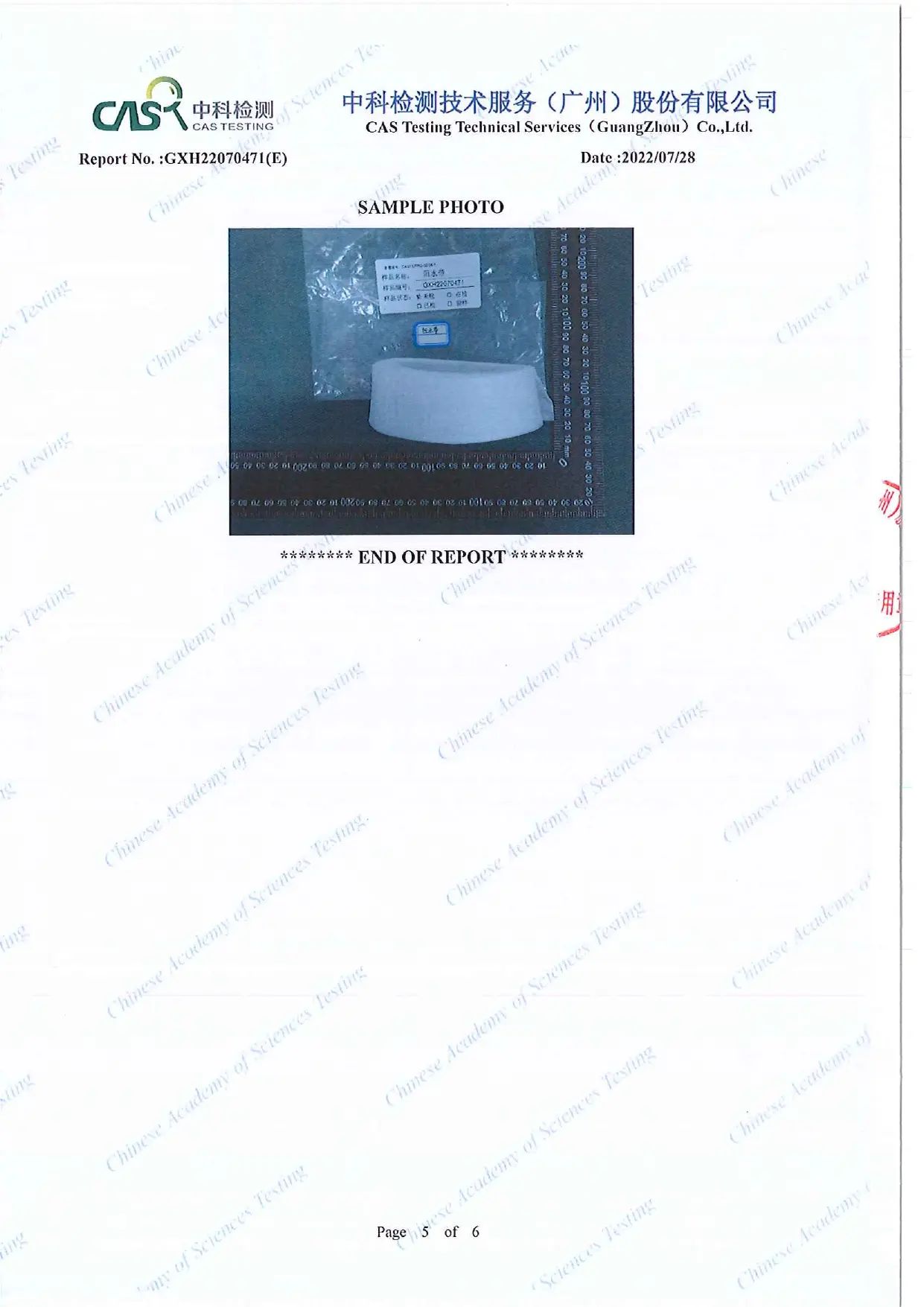

| Thermal stability | |

| a)Long-term temperature resistance(90℃,24h) Expansion height(mm) |

≥Initial value |

| b)Instantaneous high temperature(230℃,20s) Expansion height(mm) |

≥Initial value |

| Note: More specifications, please contact our sales staff. | |

Technical Parameters

| Item | Technical Parameters | |||||

| Single-sided semi-conductive water blocking tape | Double-sided semi-conductive water blocking tape | |||||

| Nominal Thickness (mm) | 0.3 | 0.4 | 0.5 | 0.3 | 0.4 | 0.5 |

| Tensile strength (N/cm) | ≥30 | ≥30 | ≥40 | ≥30 | ≥30 | ≥40 |

| Breaking elongation (%) | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

| Surface resistance (Ω) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Volume resistance (Ω·cm) | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 | ≤1×105 |

| Expansion speed (mm/min) | ≥6 | ≥8 | ≥10 | ≥8 | ≥8 | ≥10 |

| Expansion height (mm/5min) | ≥8 | ≥10 | ≥14 | ≥10 | ≥10 | ≥14 |

| Water ratio (%) | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 |

Packaging

Each pad of semi-conductive water blocking tape is packaged in a moisture-proof film bag separately, and multiple pads are wrapped in a large moisture-proof film bag, then packed into a carton, and 20 cartons are placed in a pallet.

Package size: 1.12m*1.12m*2.05m

Net weight per pallet: about 780kg

Storage

1) The product shall be kept in a clean, dry and ventilated warehouse.

2) The product should not be stacked together with flammable products or strong oxidizing agents and should not be close to fire sources.

3) The product should avoid direct sunlight and rain.

4) The product should be packed completely to avoid moisture and pollution.

5) The product shall be protected from heavy pressure and other mechanical damage during storage.

6) The storage period of the product at ordinary temperature is 6 months from the date of production. More than 6 months storage period, the product should be re-examined and only used after passing the inspection.

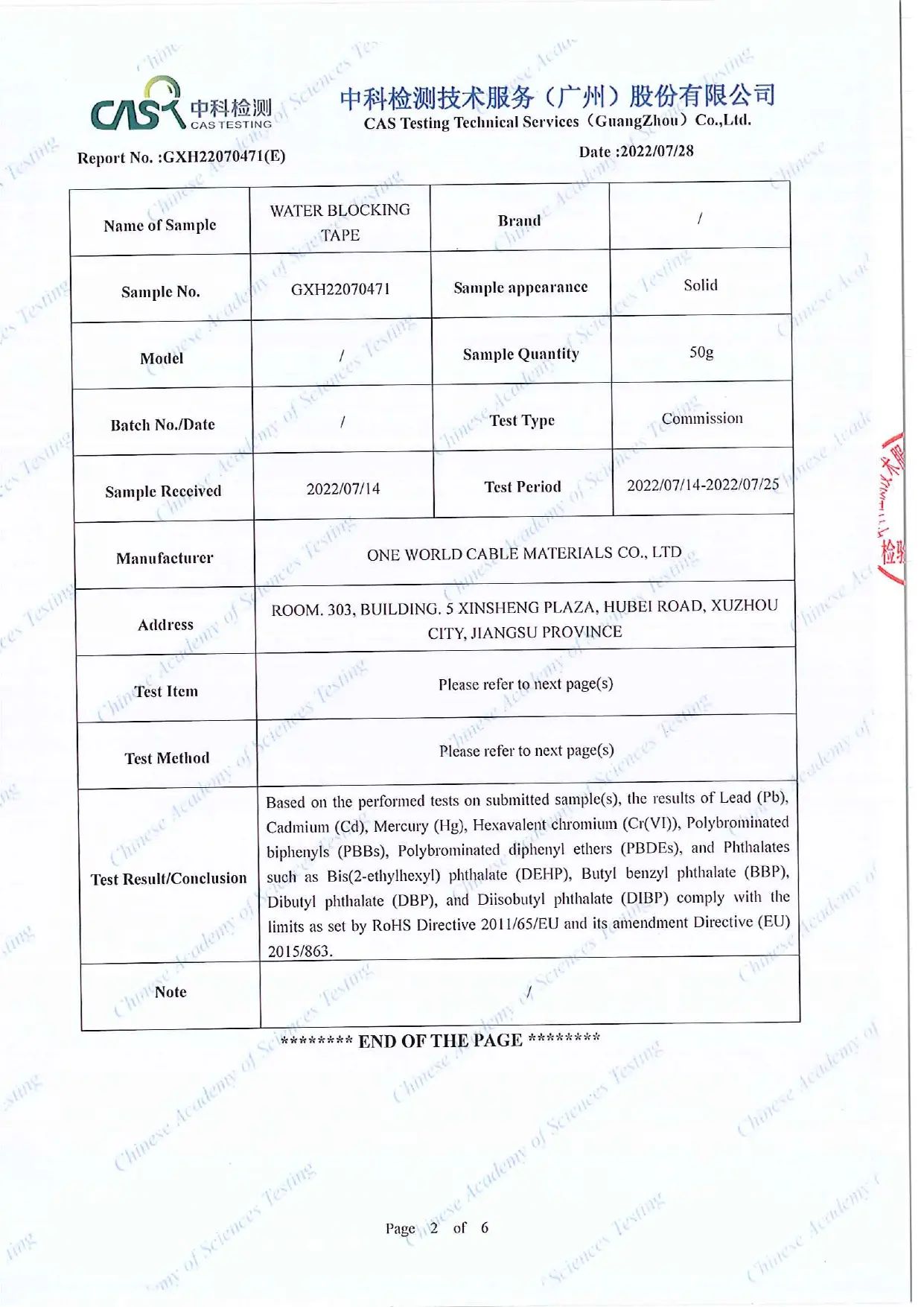

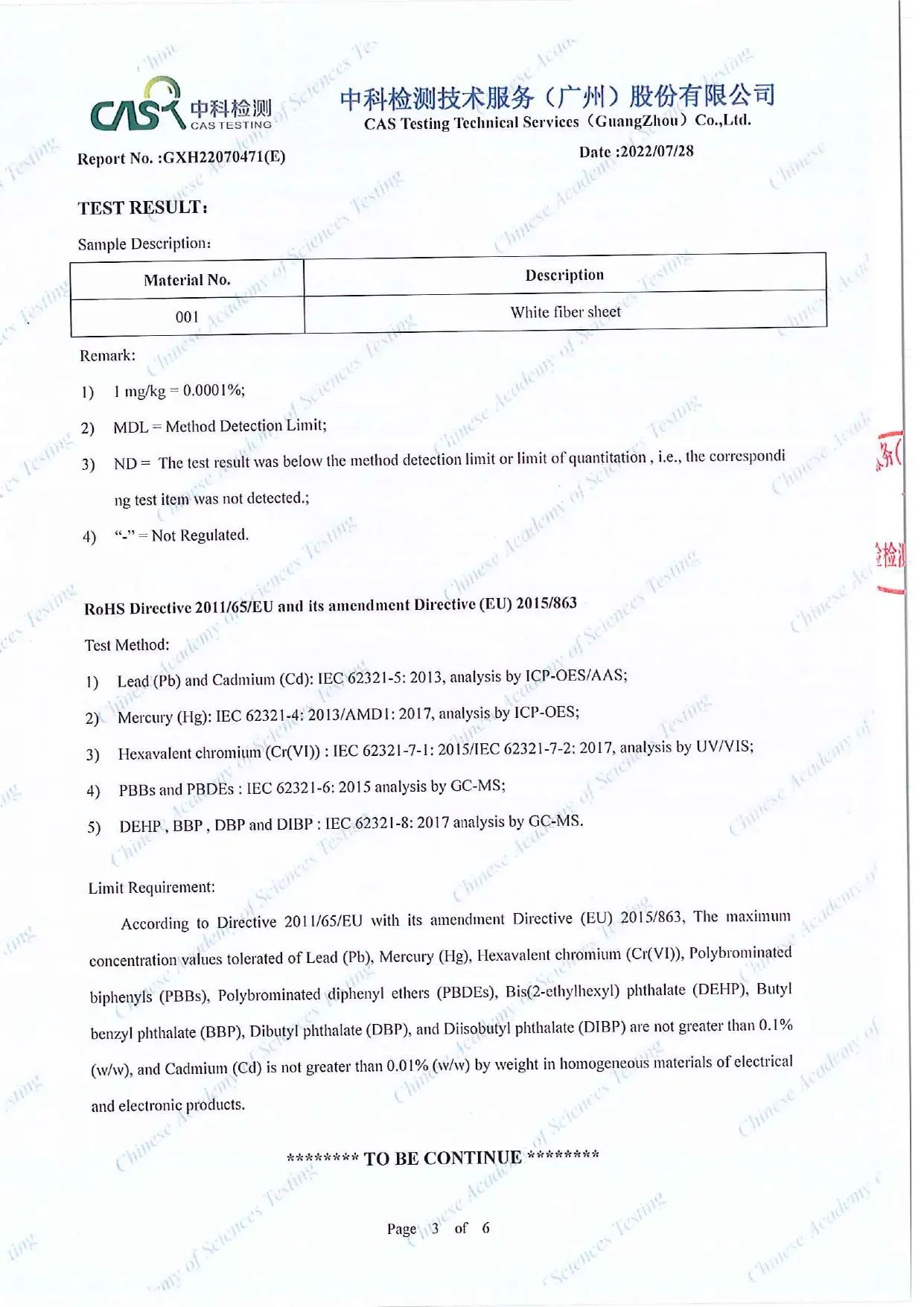

Certification

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.