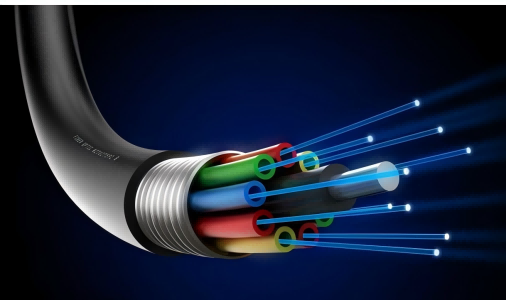

In optical fiber cable (OFC) design, selecting the right raw materials is crucial. Different operating environments—such as extreme cold, high temperatures, humidity, outdoor installation, continuous bending, or frequent movement—impose diverse requirements on optical cable materials. Here, we summarize several commonly used core materials in the industry, analyzing their performance characteristics and practical applications to help optimize your optical fiber cable design and material selection.

1. PBT (Polybutylene Terephthalate) — The Most Common Material for Loose Tubes

PBT is the most widely used material for loose tubes in optical fiber cables. Ordinary cable plastics tend to become brittle at low temperatures and soften at high temperatures. Modified PBT, for example with flexible chain segments, significantly improves low-temperature impact resistance and can meet requirements down to -40°C. Additionally, PBT offers excellent rigidity and dimensional stability at high temperatures, ensuring reliable protection for fibers under thermal stress. Its balanced performance, reasonable cost, and versatility make it a typical choice for outdoor communication cables, long-haul cables, and ADSS cable structures.

2. PP (Polypropylene) — Superior Low-Temperature Toughness and Hydrolysis Resistance

PP has gained attention in optical cable materials due to its excellent low-temperature toughness, preventing cracking in extremely cold conditions. Its hydrolysis resistance is also superior to PBT, making it suitable for humid or water-rich environments. However, PP has slightly lower modulus and rigidity compared to PBT, so its use should consider the specific cable structure. For example, lightweight cables, indoor-outdoor hybrid cables, or loose tube structures requiring higher flexibility may opt for PP as an alternative.

3. LSZH (Low Smoke Zero Halogen) — The Mainstream Eco-Friendly Cable Jacket Material

LSZH is the most widely used eco-friendly cable jacket material. High-quality LSZH formulations, achieved through specialized polymer systems and filler technologies, can meet -40°C low-temperature impact requirements and sustain long-term use at 85°C. In case of fire, LSZH releases low smoke and no halogen gases, greatly enhancing safety for indoor cables, data center cables, and public facility wiring. It also offers excellent resistance to environmental stress cracking and chemical corrosion, making it a versatile choice for both indoor and outdoor cable jackets.

4. TPU (Thermoplastic Polyurethane) — The “King” of Low-Temperature Flexibility and Abrasion Resistance

TPU is renowned for its flexibility and toughness under extreme low temperatures. Unlike PVC, TPU remains highly pliable and does not crack. It also features outstanding abrasion, oil, and tear resistance, making it ideal for moving cables, including drag chain cables, vehicular cables, mining cables, robotic cables, and industrial automation applications. Note that TPU’s high-temperature and hydrolysis resistance depend on the specific grade, so selecting high-quality formulations is critical.

5. PVC (Polyvinyl Chloride) — Cost-Effective Cable Jacket Choice with Low-Temperature Limitations

PVC remains in use for certain optical cables due to its low cost and easy processability. However, standard PVC hardens and may crack below -10°C, making it unsuitable for extreme cold conditions. Low-temperature or cold-resistant PVC can lower the glass transition temperature via plasticizers, but this may compromise mechanical strength and aging resistance. PVC is therefore better suited for cost-sensitive projects in relatively stable environments, such as standard indoor installations or temporary cable setups.

6. TPV (Thermoplastic Vulcanizate) — Combining Rubber Elasticity and Plastic Processability

TPV combines the elasticity of rubber with the processability of plastic. It offers excellent high- and low-temperature resistance, as well as outstanding weatherability and ozone resistance. TPV’s flexibility and durability make it suitable for outdoor optical cables, automotive wiring, and flexible cables. As a material, TPV balances the characteristics of TPU and PVC, providing excellent structural flexibility and environmental resilience.

7. XLPE (Crosslinked Polyethylene) — High-Temperature Insulation Material for Optical and Power Cables

XLPE, through crosslinking, enhances heat resistance and can operate continuously above 90°C. It also provides superior mechanical strength and stress resistance. While XLPE is more commonly used for power cable insulation (e.g., 1kV–35kV), it is sometimes used in optical cables for reinforcement or high-temperature applications. Its thermal and mechanical properties make it suitable for specialized optical cables in harsh environments.

Choosing Optical Cable Jacket Materials — Application Scenarios Are Key

Selecting the right optical cable materials requires more than reviewing technical data; it must also consider actual application scenarios:

Fixed Installation (outdoor, duct, aerial): LSZH, TPV, XLPE

Moving Applications (drag chains, robotics, vehicles, mining): TPU

Extreme Cold (-40°C or below): Modified PBT, PP, TPU

Indoor Cabling, Standard Use, Cost-Sensitive Projects: PVC (only recommended under specific conditions)

There is no “one-size-fits-all” solution for optical cable materials. The choice should be based on a comprehensive evaluation of cable structure, installation conditions, budget, and long-term reliability.

Post time: Nov-20-2025