The basic structure of a power cable is designed in layers, with each layer performing specific functions to ensure safe, efficient, and reliable transmission of electrical energy from the power generation source to the end-user. This modular design allows cables to adapt to various requirements, from low-voltage distribution to ultra-high-voltage transmission, and to withstand mechanical, chemical, and environmental stresses during installation and long-term operation.

The detailed structure and functions are as follows:

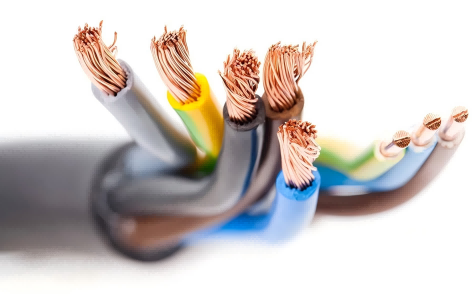

1. Conductor (Conductive Core)

Function: Serves as the core channel for transmitting electrical energy, carrying current and determining the cable’s current-carrying capacity and conductivity efficiency.

Materials and Processes: Typically made of highly conductive annealed copper (low resistivity, good flexibility) or hard-drawn aluminum conductors. To balance flexibility and strength, conductors are often formed by regularly stranding multiple fine wires. Their cross-sectional shapes are optimized to tightly fill the insulation space and improve heat dissipation.

2. Shielding Layers

Function: This pair of semiconducting layers forms an “equalizing system,” crucial for ensuring uniform electric field distribution in medium and high-voltage cables.

Conductor Shield: Extruded tightly onto the conductor surface, it fills microscopic irregularities and interstices within the stranded conductor, preventing corona discharge and local electrical treeing.

Insulation Shield: Fitted tightly onto the outer surface of the insulation layer, it uniforms the electric field and provides a smooth transition to the outer metallic shield layer.

Material: Both are crosslinkable semiconductive materials, with volume resistivity typically controlled within the range of 10² to 10⁵ Ω·cm.

3. Insulation Layer

Function: Provides electrical isolation, withstanding operating voltage and overvoltages to prevent breakdown or leakage.

Materials: Mainstream material is Cross-Linked Polyethylene (XLPE). Ethylene Propylene Rubber (EPR) is used for medium-voltage and high-flexibility applications. Polyvinyl Chloride (PVC) is predominantly used in low-voltage distribution networks.

4. Metallic Shield Layer

Function: Provides a path for fault current, electromagnetic shielding, and grounding protection.

Forms: Copper tape shielding, copper wire braid shielding, or corrugated metallic sheaths (which also provide a radial water barrier function).

5. Filling Layer

Function: Fills voids in multi-core cables to maintain structural stability, and provides auxiliary cushioning and moisture protection.

Material: Non-hygroscopic materials such as polypropylene (PP) ripcord or water-blocking ropes.

6. Inner Sheath

Function: Protects the metallic shield layer from corrosion and provides a preliminary radial water and moisture barrier.

Materials: Extruded Polyethylene (PE) or Polyvinyl Chloride (PVC) sheaths. For applications requiring good water-blocking performance, aluminum-polyethylene laminated sheaths are often used.

7. Armor Layer

Function: Provides mechanical protection against crushing during direct burial, pulling during installation, and tension during submarine laying.

Types: Steel tape armor (mainly for compressive resistance) or steel wire armor (for tensile strength).

8.Outer Sheath

Function: Outermost layer of protection, resistant to environmental corrosion.

Material: PVC or PE sheath material, with the possibility of developing flame-retardant, halogen-free, and low-smoke special sheath materials.

9. Special Constructions

Waterproofing Structure: Corrugated metallic sheaths or water-blocking powder/tapes/gels.

Fire Protection Structure: Ceramifiable silicone rubber, mica tapes, or low-smoke zero-halogen (LSZH) materials.

Smart Integration: Some cables integrate optical fiber units for temperature measurement or communication.

10. Structure Example (High-Voltage Single-Core Cable)

Copper Conductor → Conductor Shield → XLPE Insulation → Insulation Shield → Corrugated Metallic Shield → PE Inner Sheath → Steel Wire Armor → Outer Sheath.

11. Summary

A power cable is a precisely engineered system product. The selection of materials and the implementation of processes for each layer profoundly influence the cable’s transmission efficiency, service life, and safety level. Modern cable technology is developing towards higher voltage levels, greater capacity, higher reliability, increased intelligence, and enhanced environmental sustainability.

Post time: Dec-18-2025