Low-temperature resistant cables (often referred to as "cold-proof cables") are a type of special cable designed for extreme low-temperature environments. Their core lies in the use of special low-temperature resistant materials, enabling them to maintain excellent electrical and mechanical properties even under harsh conditions as low as -40°C to -60°C. In contrast, standard cables experience rapid performance degradation in such environments and cannot guarantee safe and reliable operation.

1. Fundamental Difference: Material Selection

Material is the core factor determining a cable's low-temperature resistance, primarily reflected in the insulation and sheathing.

Insulation Materials

Low-Temperature Resistant Cables: Employ special insulation materials such as fluoropolymers, Polyurethane (PU), low-temperature modified PVC, and low-temperature Cross-Linked Polyethylene (XLPE). These materials possess molecular structures with low-temperature flexibility, ensuring the insulation layer does not crack or shrink under extreme cold conditions.

Standard Cables: Typically use standard PVC or XLPE, which rapidly hardens and embrittles at low temperatures, leading to insulation failure.

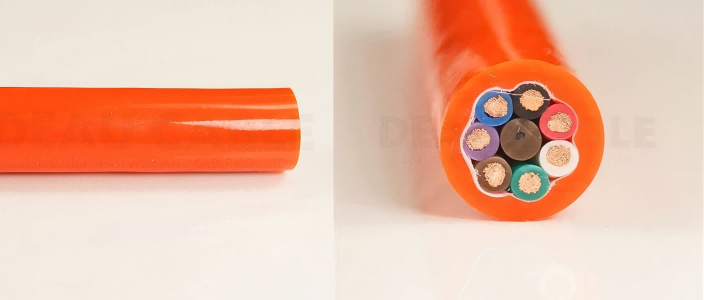

Sheathing Materials

Low-Temperature Resistant Cables: The outer sheath often uses Nitrile Rubber, Chloroprene Rubber (CR), EPDM, Thermoplastic Polyurethane (TPU), or specially formulated low-temperature LSZH materials. These materials are not only low-temperature resistant but also offer excellent abrasion resistance, oil resistance, UV resistance, and weather resistance, providing comprehensive protection for the cable.

Standard Cables: The sheath is mostly made of standard PVC or Polyethylene (PE), which is prone to aging and cracking under the combined stress of low temperatures and complex environments, losing its protective function.

2. Structural and Performance Differences

Based on material properties, the two types of cables exhibit significant differences in structural design and final performance.

Conductor and Structural Design

Low-Temperature Resistant Cables:

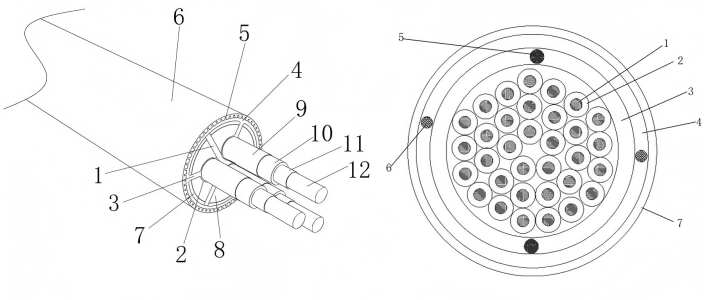

Conductor: Often employs multi-strand, super-fine, finely bunched oxygen-free copper or tinned copper wires, significantly enhancing the cable's flexibility and oxidation resistance.

Structure: Optimized core lay length and potential addition of tensile fibers, anti-twist layers, or buffer layers to enhance bending, torsion, and impact resistance, suitable for moving applications.

Standard Cables: The structure is designed primarily for static installation in ambient temperatures, with lower conductor stranding flexibility and fewer mechanical reinforcements.

Key Performance Comparison

Low-Temperature Resistant Cables:

Mechanical Performance: Maintains high flexibility, high tensile strength, and bending fatigue resistance even in extreme cold.

Electrical Performance: Capable of maintaining stable insulation resistance and voltage withstand levels, with excellent conductivity.

Environmental Tolerance: Possesses outstanding abrasion resistance, chemical corrosion resistance, and weather resistance.

Standard Cables:

Mechanical Performance: Loses flexibility at low temperatures; the sheath and insulation are prone to cracking, making them highly susceptible to mechanical damage.

Electrical Performance: Insulation resistance decreases significantly, the risk of breakdown increases, posing serious potential safety hazards.

3. Application Scenarios and Economic Considerations

Performance differences directly determine their respective application fields and economic viability.

Application Scenarios

Low-Temperature Resistant Cables: Are the necessary choice for areas such as polar regions, industrial cold storage facilities, high-altitude areas, ship decks, outdoor wind power, deep-sea equipment, metallurgy, petrochemicals, aerospace, and Antarctic research.

Standard Cables: Are only suitable for indoor power distribution, and ordinary industrial and civil buildings in temperate climate zones and other ambient temperature environments.

Installation and Maintenance

Low-Temperature Resistant Cables: Designed for low-temperature installation; in some cases, can be used with pre-heating measures, offering high installation convenience, strong system reliability, and low maintenance frequency.

Standard Cables: Installation in low-temperature environments is strictly prohibited, as it can easily cause permanent damage to the insulation layer, resulting in high subsequent maintenance costs.

Cost Analysis

Low-Temperature Resistant Cables: Due to the use of special materials and complex processes, the initial procurement cost is higher. However, within their designed environment, they offer reliable performance and a long service life, resulting in a lower total cost of ownership.

Standard Cables: Have a low initial cost, but if misused in low-temperature environments, they will lead to frequent failures, downtime, and safety incidents, resulting in a higher overall cost.

Summary

Choosing between low-temperature resistant cables and standard cables is not a simple decision based solely on cost, but a systems engineering decision fundamentally determined by the temperature conditions of the application environment. Correct selection is the primary prerequisite for ensuring the safe, stable, and long-term operation of power systems in low-temperature environments.

Post time: Nov-28-2025