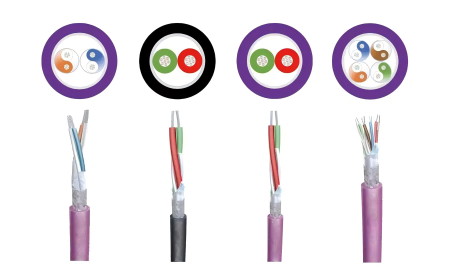

With the development of intelligence in the global shipping industry, marine bus cables play an increasingly critical role in shipboard data communication and automation systems. They connect sensors, controllers, and actuators within vessels, supporting functions such as automatic control, remote monitoring, and energy efficiency management.

To adapt to harsh marine environments characterized by high salt spray, high humidity, and strong electromagnetic interference, marine bus cables adopt specialized materials and structural designs, offering corrosion resistance, flame retardancy, low smoke halogen-free performance, and excellent EMI shielding to ensure long-term stable operation. This article focuses on the structural design of marine bus cables.

Basic Structure Overview

1. Conductor

Marine bus cables typically use stranded tinned copper conductors. Stranded conductors ensure good electrical performance and mechanical lifespan while facilitating installation. Compared with bare copper conductors, tinned copper conductors provide superior resistance to salt spray corrosion.

The use of stranded tinned copper conductors helps improve issues such as high-frequency attenuation, bending fatigue, salt spray corrosion, low-temperature brittleness, and limited installation space, making them highly suitable for marine bus cable applications.

2. Insulation

Foamed polyethylene (Foam-PE) is commonly used as the insulation material for marine bus cables. Foamed polyethylene insulation effectively reduces the dielectric constant, thereby lowering signal attenuation, while also providing longitudinal water-blocking capability. In addition, the use of Foam-PE helps reduce cable weight, contributing to overall vessel weight reduction.

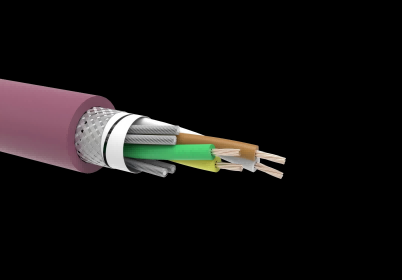

3. Shielding

The shielding structure of marine bus cables is similar to that of marine network cables and generally consists of plastic coated aluminum tape combined with tinned copper wire braiding. The shielding layer is designed to block electromagnetic interference and ensure stable signal transmission.

Typically, the aluminum foil thickness is ≥ 0.012 mm with 100% coverage, while the tinned copper braid usually uses 0.12 mm single wires, with a minimum braid coverage of 60%.

In most cases, marine bus cables adopt a double-shielding structure of plastic coated aluminum tape plus tinned copper braid. This composite shielding can enhance shielding effectiveness to 70–90 dB @ 30 MHz.

In addition, a solid or stranded tinned copper drain wire is often included to provide additional grounding.

4. Sheath

The sheath serves to protect the cable from external environmental influences. As the first line of defense, the sheath material of marine bus cables must offer resistance to salt spray corrosion, abrasion, and flame propagation to ensure reliability and safety in harsh conditions.

To enhance the safety of shipboard communication systems, marine bus cables typically use low-smoke halogen-free flame-retardant polyolefin (LSZH-SHF1) sheath materials. These materials do not emit toxic smoke during combustion and comply with IEC 60332-1 single-cable flame retardancy, IEC 60332-3-22 bundled flame retardancy, as well as IEC 60754-1/2 and IEC 61034-1/2 low-smoke halogen-free requirements. This not only reduces risks to crew safety in the event of fire but also minimizes environmental impact.

In offshore platforms and similar applications, marine bus cables may also be required to exhibit oil and mud resistance. In such cases, LSZH-SHF2 materials with enhanced oil resistance, or LSZH-SHF2-MUD materials with additional mud resistance, are selected for the sheath.

5. Special Structures

Under normal conditions, the standard marine bus cable structure consisting of conductor, insulation, shielding, and sheath is sufficient for most marine applications. When higher performance requirements are imposed, the cable structure can be modified accordingly.

For example, in applications requiring additional mechanical protection, an armor layer may be added, along with an extra outer sheath to form a double-sheathed armored structure. The armor layer is typically made of galvanized steel wire braid, which significantly enhances mechanical strength and protects the cable from damage in harsh environments.

When marine bus cables are used in fire-resistant applications, mica tape wrapping is added over the insulation layer to meet IEC 60331 fire-resistance standards and safe return-to-port requirements.

Conclusion

The structural design and material selection of marine bus cables are key factors enabling stable and reliable signal transmission in harsh marine environments. Whether it is tinned copper conductors, foamed polyethylene insulation, or low-smoke halogen-free flame-retardant sheaths, these structural designs have undergone extensive optimization and refinement.

Well-engineered cable structures ensure continuous and reliable operation of marine bus cables in marine environments where high temperatures, salt spray corrosion, and strong electromagnetic interference coexist.

Post time: Jan-21-2026