Choosing between silicone and PVC wire for your project isn't just about cost; it's about performance, safety, and long-term reliability. So, which one is truly best for your specific application? This guide breaks down the key differences to help you make an informed decision.

Silicone wires and polyvinyl chloride (PVC) wires are two fundamental and widely used products in the wire and cable industry. Their material properties directly determine the applicable scenarios and service life of the cables. The following analysis is conducted from four aspects: material structure, performance comparison, industry applications, and selection recommendations, providing a systematic reference for wire design and material selection.

1. Material Structure and Process Characteristics

Silicone Wires: Typically use high-purity silicone rubber insulation material. The outer layer can be paired with a halogen-free flame-retardant sheath material, formed through a high-temperature vulcanization process to create a flexible and stable insulation system.

PVC Wires: Primarily based on polyvinyl chloride (PVC) compound cable materials. Hardness and weather resistance are adjusted using additives like plasticizers and stabilizers. They are produced via an extrusion process, offering controllable costs and high processing efficiency.

2. Comprehensive Performance Comparison

Temperature Range:

Silicone wires: Long-term temperature resistance from -60°C to +200°C, suitable for high-temperature environments such as motors, heating elements, and automotive engine compartments.

PVC wires: Standard temperature resistance from -15°C to +105°C, widely used in indoor electrical appliances and general power distribution environments.

Environmental Adaptability:

Silicone wires: Possess excellent low-temperature resistance, ozone resistance, and UV resistance, demonstrating reliability in outdoor, cold storage, and mobile equipment applications.

PVC wires: May become brittle or chemically corrode in low-temperature or highly chemical environments; suitable for mild operating conditions.

Safety and Environmental Protection:

Silicone wires: Emit low smoke and are halogen-free when burning, complying with safety regulations in fields like medical and transportation.

PVC wires: Have good flame retardancy but contain halogens, requiring attention to specific environmental protection requirements.

3. Industry Application Scenarios

Silicone Wires: Commonly used in high-end fields such as new energy vehicle high-voltage wiring harnesses, photovoltaic cables, robotic cables, and high-temperature-resistant specialty cables. Their material properties of aging resistance and stable electrical performance support long-term, reliable operation.

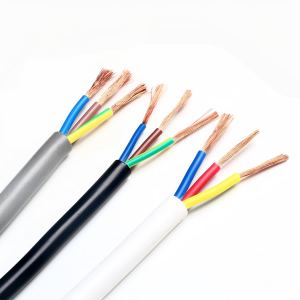

PVC Wires: Widely applied in scenarios like building wiring, low-voltage power cables, home appliance wiring, and internal connection wires for electronic devices, balancing performance and cost advantages.

4. Selection Recommendations and Technical Material Support

Wire selection should be based on a comprehensive evaluation of actual operating conditions, including temperature, mechanical stress, chemical exposure, and environmental certification requirements. For high-temperature, low-temperature, or chemically complex environments, cable solutions utilizing high-performance silicone rubber materials as the core are recommended. For general industrial and civilian applications, environmentally friendly PVC cable compounds still offer significant cost-performance advantages.

As a leading supplier of cable materials in the industry, ONE WORLD provides a full range of products encompassing silicone insulation materials and PVC cable compounds. Our related materials have obtained international certifications such as UL and RoHS. We provide customized formulation support for specific application scenarios like new energy vehicle cables, photovoltaic cables, and industrial robotic cables. We are committed to providing global customers with technologically advanced, compliant, and reliable tailored overall cable material solutions.

Post time: Dec-30-2025