As modern society develops, networks have become an indispensable part of daily life, and network signal transmission relies on network cables (commonly referred to as Ethernet cables). As a mobile modern industrial complex at sea, marine and offshore engineering is becoming increasingly automated and intelligent. The environment is more complex, placing higher demands on the structure of Ethernet cables and the cable materials used. Today, we'll briefly introduce the structural features, classification methods, and key material configurations of marine Ethernet cables.

1.Cable Classification

(1).According to Transmission Performance

The Ethernet cables we commonly use are typically made with copper conductor twisted pair structures, containing single or multi-stranded copper conductors, PE or PO insulation materials, twisted in pairs, and then four pairs formed into a complete cable. Based on performance, different grades of cables can be selected:

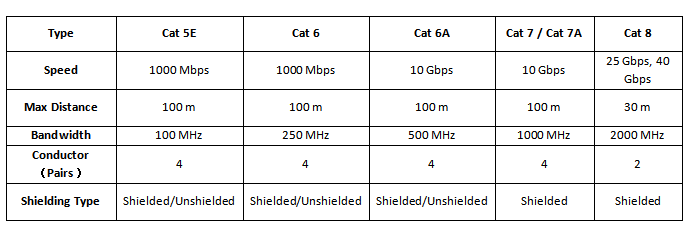

Category 5E (CAT5E): Outer sheath is usually made of PVC or low-smoke halogen-free polyolefin, with a transmission frequency of 100MHz and a maximum speed of 1000Mbps. It is widely used in home and general office networks.

Category 6 (CAT6): Uses higher-grade copper conductors and high-density polyethylene (HDPE) insulation material, with a structural separator, increasing bandwidth to 250MHz for more stable transmission.

Category 6A (CAT6A): Frequency increases to 500MHz, transmission rate reaches 10Gbps, typically uses aluminum foil Mylar tape as pair shielding material, and is combined with high-performance low-smoke halogen-free sheath material for use in data centers.

Category 7 / 7A (CAT7/CAT7A): Uses 0.57mm oxygen-free copper conductor, each pair shielded with aluminum foil Mylar tape + overall tinned copper wire braid, enhancing signal integrity and supporting 10Gbps high-speed transmission.

Category 8 (CAT8): Structure is SFTP with double-layer shielding (aluminum foil Mylar tape for each pair + overall braid), and sheath is typically high flame-retardant XLPO sheath material, supporting up to 2000MHz and 40Gbps speed, suitable for inter-equipment connections in data centers.

(2). According to Shielding Structure

According to whether shielding materials are used in the structure, Ethernet cables can be divided into:

UTP (Unshielded Twisted Pair): Uses only PO or HDPE insulation material with no additional shielding, low cost, suitable for environments with minimal electromagnetic interference.

STP (Shielded Twisted Pair): Uses aluminum foil Mylar tape or copper wire braid as shielding material, enhancing interference resistance, suitable for complex electromagnetic environments.

Marine Ethernet cables often face strong electromagnetic interference, requiring higher shielding structures. Common configurations include:

F/UTP: Uses aluminum foil Mylar tape as overall shielding layer, suitable for CAT5E and CAT6, commonly used in onboard control systems.

SF/UTP: Aluminum foil Mylar tape + bare copper braid shielding, enhancing overall EMI resistance, commonly used for marine power and signal transmission.

S/FTP: Each twisted pair uses aluminum foil Mylar tape for individual shielding, with an outer layer of copper wire braid for overall shielding, paired with high flame-retardant XLPO sheath material. This is a common structure for CAT6A and above cables.

2. Differences in Marine Ethernet Cables

Compared to land-based Ethernet cables, marine Ethernet cables have clear differences in material selection and structural design. Due to the harsh marine environment—high salt mist, high humidity, strong electromagnetic interference, intense UV radiation, and flammability—cable materials must meet higher standards for safety, durability, and mechanical performance.

(1).Standard Requirements

Marine Ethernet cables are usually designed according to IEC 61156-5 and IEC 61156-6. Horizontal cabling typically uses solid copper conductors combined with HDPE insulation materials to achieve better transmission distance and stability; patch cords in data rooms use stranded copper conductors with softer PO or PE insulation for easier routing in tight spaces.

(2).Flame Retardancy and Fire Resistance

To prevent fire spread, marine Ethernet cables often use low-smoke halogen-free flame-retardant polyolefin materials (such as LSZH, XLPO, etc.) for sheathing, meeting IEC 60332 flame retardant, IEC 60754 (halogen-free), and IEC 61034 (low smoke) standards. For critical systems, mica tape and other fire-resistant materials are added to meet IEC 60331 fire-resistance standards, ensuring communication functions are maintained during fire incidents.

(3). Oil Resistance, Corrosion Resistance, and Armoring Structure

In offshore units such as FPSOs and dredgers, Ethernet cables are often exposed to oil and corrosive media. To improve sheath durability, cross-linked polyolefin sheath materials (SHF2) or mud-resistant SHF2 MUD materials are used, compliant with NEK 606 chemical resistance standards. To further enhance mechanical strength, cables can be armored with galvanized steel wire braid (GSWB) or tinned copper wire braid (TCWB), providing compression and tensile strength, along with electromagnetic shielding to protect signal integrity.

(4). UV Resistance and Aging Performance

Marine Ethernet cables are often exposed to direct sunlight, so sheath materials must have excellent UV resistance. Typically, polyolefin sheathing with carbon black or UV-resistant additives is used and tested under UL1581 or ASTM G154-16 UV aging standards to ensure physical stability and extended service life in high UV environments.

In summary, every layer of marine Ethernet cable design is closely tied to the careful selection of cable materials. High-quality copper conductors, HDPE or PO insulation materials, aluminum foil Mylar tape, copper wire braid, mica tape, XLPO sheath material, and SHF2 sheath materials together form a communication cable system capable of withstanding harsh marine environments. As a cable material supplier, we understand the importance of material quality to the performance of the entire cable and are committed to providing reliable, safe, and high-performance material solutions for the marine and offshore industries.

Post time: Jun-16-2025