High-temperature resistant cables refer to special cables that can maintain stable electrical and mechanical performance in high-temperature environments. They are widely used in aviation, aerospace, petroleum, steel smelting, new energy, military industry, and other fields.

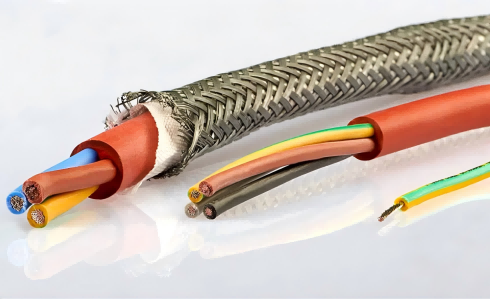

The raw materials for high-temperature resistant cables mainly include conductor materials, insulating materials, and sheathing materials. Among them, the conductor should have excellent conductivity and high-temperature resistance; the insulation layer needs to have characteristics such as high-temperature resistance, wear resistance, and chemical corrosion resistance; the sheath should possess functions such as high-temperature resistance, anti-aging, oil resistance, and mechanical protection.

The conductor of high-temperature resistant cables is generally made of copper or aluminum, drawn into wires of different diameters through a wire drawing machine. During the drawing process, parameters such as drawing speed, mold temperature, and coolant temperature must be strictly controlled to ensure the surface smoothness and mechanical properties of the wires meet requirements.

The insulation layer is a core component of high-temperature resistant cables, and its preparation process directly affects the overall performance of the cable. Polymer materials such as polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), polyether ether ketone (PEEK), or ceramic silicone rubber are typically used to form the insulation layer through extrusion or molding processes. During this process, temperature, pressure, and production line speed must be precisely controlled to ensure the insulation layer has uniform thickness, no defects, and stable electrical insulation performance.

The sheath serves as the outer protective layer of the cable, primarily used to protect against mechanical damage and harsh environmental erosion. Common sheathing materials include polyvinyl chloride (PVC), polyethylene (PE), cross-linked polyethylene (XLPE), and special fluoroplastics. During the extrusion molding process, extrusion temperature, head pressure, and traction speed must be strictly controlled to ensure the sheath is dense, uniformly thick, and has a smooth appearance.

The following key points must be strictly controlled during the production process to ensure the quality of the finished cable:

1.Temperature Control: Temperature must be precisely controlled at each process stage to ensure material performance and process stability.

2.Pressure Control: Pressure must be reasonably controlled during extrusion or molding to ensure the thickness and quality of the insulation and sheath.

3.Speed Control: Wire speed must be strictly controlled during processes such as drawing and extrusion to ensure production efficiency and product consistency.

4.Drying Treatment: Some polymer materials require pre-drying to avoid defects such as bubbles during processing.

5.Quality Inspection: Strict inspections must be carried out during the production process and upon completion of the product, including appearance inspection, dimensional measurement, electrical performance testing, and high-temperature aging tests, to ensure the product meets standards and usage requirements.

The production of high-temperature resistant cables involves multiple precise steps, and full-process quality control must be implemented to obtain qualified products. By comprehensively mastering raw material selection, process parameter adjustment, and manufacturing process management, the production efficiency and product consistency of cables can be significantly improved. Additionally, promoting technological innovation and equipment upgrades, introducing automated production lines and intelligent detection systems, will further enhance production quality and industry competitiveness, opening up broader development prospects for the manufacturing of high-temperature resistant cables.

As a professional supplier of cable materials, ONE WORLD is always committed to providing global customers with high-quality comprehensive cable material solutions. The company’s product system includes special materials mentioned in the article, such as polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), polytetrafluoroethylene (PTFE), as well as high-performance tapes like Mylar Tape, Water Blocking Tape, and Semi-conductive Water Blocking Tape, and high-end optical cable materials such as PBT, FRP, and Aramid Yarn. We adhere to technological innovation as the development engine, continuously optimizing material formulas and production processes to provide customers with a full range of products with excellent performance and stable quality, helping cable manufacturing enterprises enhance product competitiveness and jointly promoting the technological progress and innovative development of the cable industry.

Post time: Sep-19-2025