Produktuak

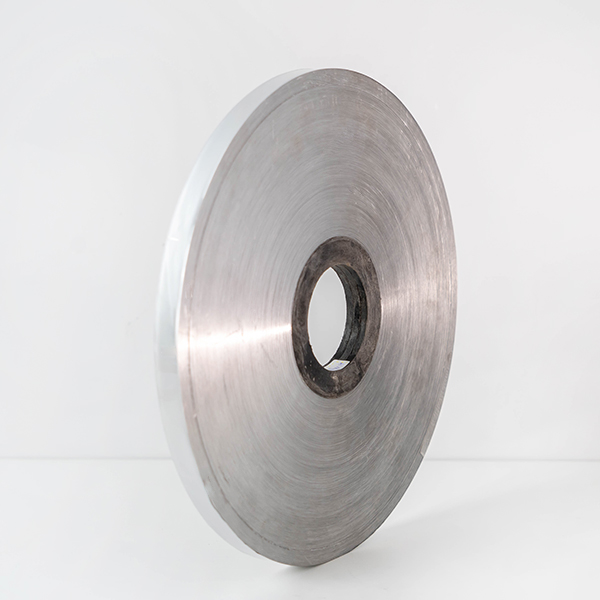

Plastikoz estalitako aluminiozko zinta – Plastikozko aluminiozko papera

Produktuaren aurkezpena

Plastikoz estalitako aluminiozko zinta metalezko konpositezko zinta bat da, kalandratzeko aluminiozko zintarekin egina, oinarrizko material gisa harikortasun ona duena, eta alde bakarreko edo alde bikoitzeko polietileno (PE) plastikozko geruza konposatu batekin edo kopolimero plastikozko geruza batekin laminatua.

Luzerako bilgarri metodoa erabiliz, aluminiozko plastikozko paperak kablearen edo kable optikoaren zorro konposatu bat osa dezake kanpoko polietilenozko zorro estrusoarekin, ura blokeatzeko, hezetasuna blokeatzeko eta babesteko funtzioa betetzeko. Tolestura-errendimendua hobetzeko, korrugatu egin daiteke kableen/kable optikoen malgutasuna hobetzeko.

Kopolimero motako alde bakarreko/alde bikoitzeko aluminiozko plastikozko papera eta polietileno motako alde bakarreko/alde bikoitzeko plastikozko estaldura duen aluminiozko zinta eskaintzen ditugu. Plastikozko estaldura duen aluminiozko zinta metalezko konpositezko zinta bat da, kalandratzeko aluminiozko zintarekin egindakoa, harikortasun oneko oinarrizko material gisa, eta alde bakarreko edo alde bikoitzeko polietileno (PE) plastikozko konpositezko geruza batekin edo kopolimero plastikozko geruza batekin laminatua.

Luzerako bilgarri metodoa erabiliz, plastikoz estalitako aluminiozko zintak kablearen edo kable optikoaren zorro konposatu bat osa dezake kanpoko polietilenozko zorro estrusoarekin, ura blokeatzeko, hezetasuna blokeatzeko eta babesteko funtzioa betetzeko. Tolestura-errendimendua hobetzeko, korrugatu egin daiteke kableen/kable optikoen malgutasuna hobetzeko.

Kopolimero motako alde bakarreko/alde bikoitzeko plastikozko aluminiozko papera, polietileno motako alde bakarreko/alde bikoitzeko plastikozko estaldura duen aluminiozko zinta eskaintzen ditugu.

Guk eskaintzen dugun plastikoz estalitako aluminiozko zintak gainazal leuna, uniformea, erresistentzia handikoa, bero-zigilatzeko erresistentzia handikoa eta betegarri-konposatuekin bateragarritasun ona ditu. Bereziki, kopolimero motako plastikoz estalitako aluminiozko zintak errendimendu ona du tenperatura baxuagoetan lotura lortzeko.

Aluminiozko paper plastikoak bi kolore ditu: naturala eta urdina.

Aplikazioa

Batez ere komunikazio-kableetan, energia-kableetan, kanpoko kable optikoetan eta beste kable batzuetan erabiltzen da, eta kanpoko zorroarekin zorro konposatu bat osatzen du, ura blokeatzeko, hezetasuna blokeatzeko eta babesteko eginkizuna betetzen duena.

Parametro teknikoak

Produktuaren zehaztapenak

| Lodiera Total Nominala (mm) | Aluminiozko oinarriaren lodiera nominala (mm) | Plastikozko geruzaren lodiera nominala (mm) | |

| Alde bakarrekoa | Bi aldeetakoa | ||

| 0,16 | 0,22 | 0.1 | 0,058 |

| 0,21 | 0,27 | 0,15 | |

| 0,26 | 0,32 | 0,2 | |

| Oharra: Zehaztapen gehiago nahi izanez gero, jarri harremanetan gure salmenta-taldearekin. | |||

Parametro teknikoak

| Elementua | Parametro teknikoak | |

| Trakzio-indarra (MPa) | ≥65 | |

| Haustura-luzapena (%) | ≥15 | |

| Zuritze-indarra (N/cm) | ≥6.13 | |

| Bero Zigiluaren Indarra (N/cm) | ≥17.5 | |

| Ebaketa-indarra | Aluminiozko zinta hausten denean edo plastikozko geruzen arteko bero-zigilu eremuan kalteak gertatzen direnean. | |

| Gelatina erresistentzia (68 ℃ ± 1 ℃, 168 h) | Ez dago delaminaziorik aluminiozko zintaren eta plastikozko geruzaren artean. | |

| Indar dielektrikoa | Alde bakarrekoa plastikoz estalitako aluminiozko zinta | 1kV korronte zuzena, 1min, Matxurarik gabe |

| Bi aldeetakoa plastikoz estalitako aluminiozko zinta | 2kV korronte zuzena, 1 min, Matxurarik gabe | |

Ontziratzea

1) Bobinean dagoen aluminiozko plastikozko papera bilgarri-filmarekin bildu eta egurrezko kaxa batean sartzen da.

2) Plastikoz estalitako aluminiozko zinta pastillan bilduta dago film batekin eta ondoren kartoi batean pilatzen da lehortzailea duena, eta gero paletean jartzen da.

Biltegiratzea

1) Produktua biltegi garbi, lehor eta aireztatu batean gorde behar da. Biltegia aireztatuta eta fresko egon behar da, eguzki-argia zuzenean, tenperatura altuak, hezetasun handia eta abar saihestuz, produktuak puztu, oxidatu eta bestelako arazoak saihesteko.

2) Produktua ez da produktu sukoiekin batera pilatu behar, eta ez da su iturrietatik gertu egon behar.

3) Produktua guztiz ontziratu behar da hezetasuna eta kutsadura saihesteko.

4) Produktua presio handitik eta bestelako kalte mekanikoetatik babestu behar da biltegiratzean.

5) Produktua ezin da aire zabalean gorde, baina lona bat erabili behar da denbora laburrean aire zabalean gorde behar denean.

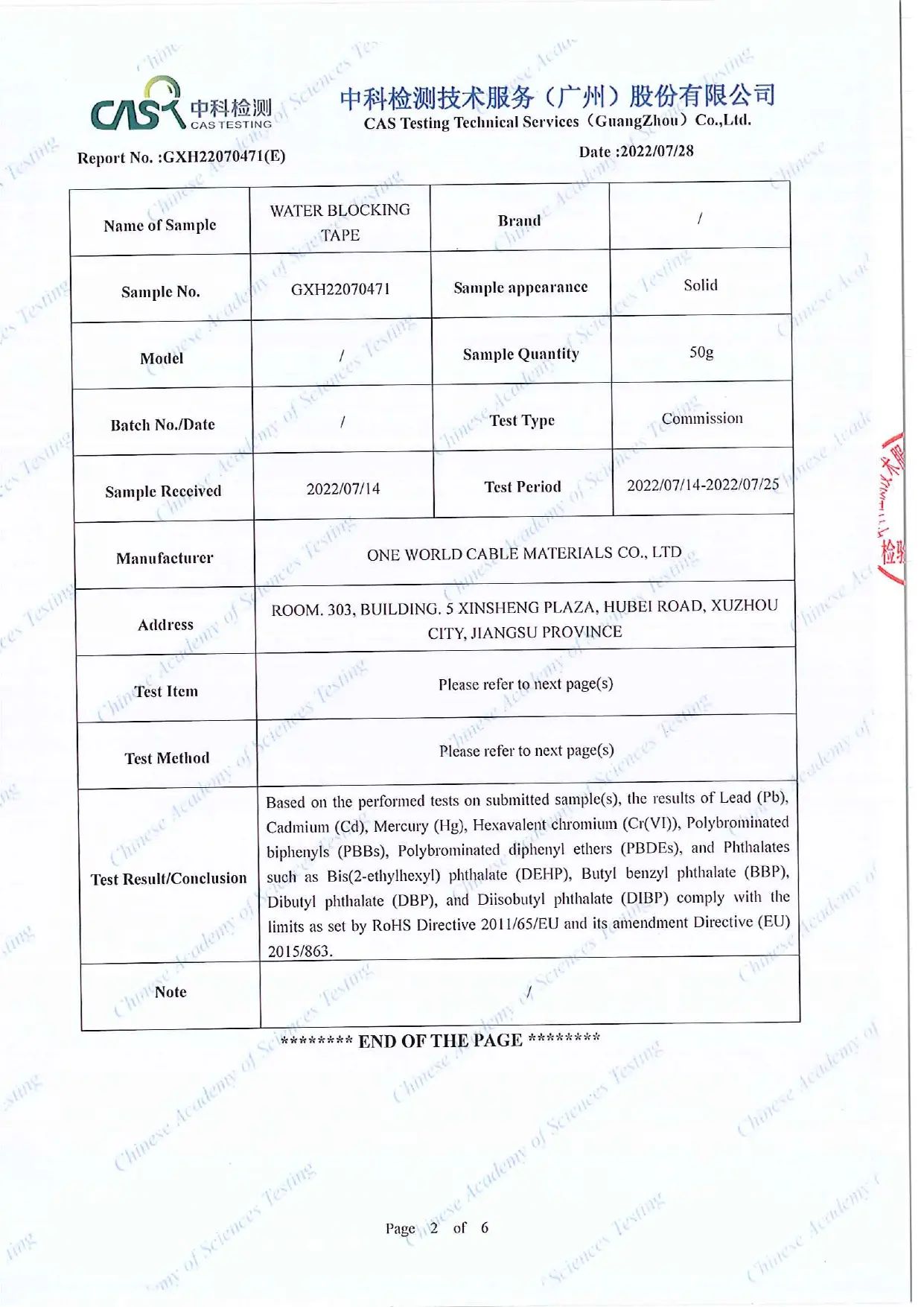

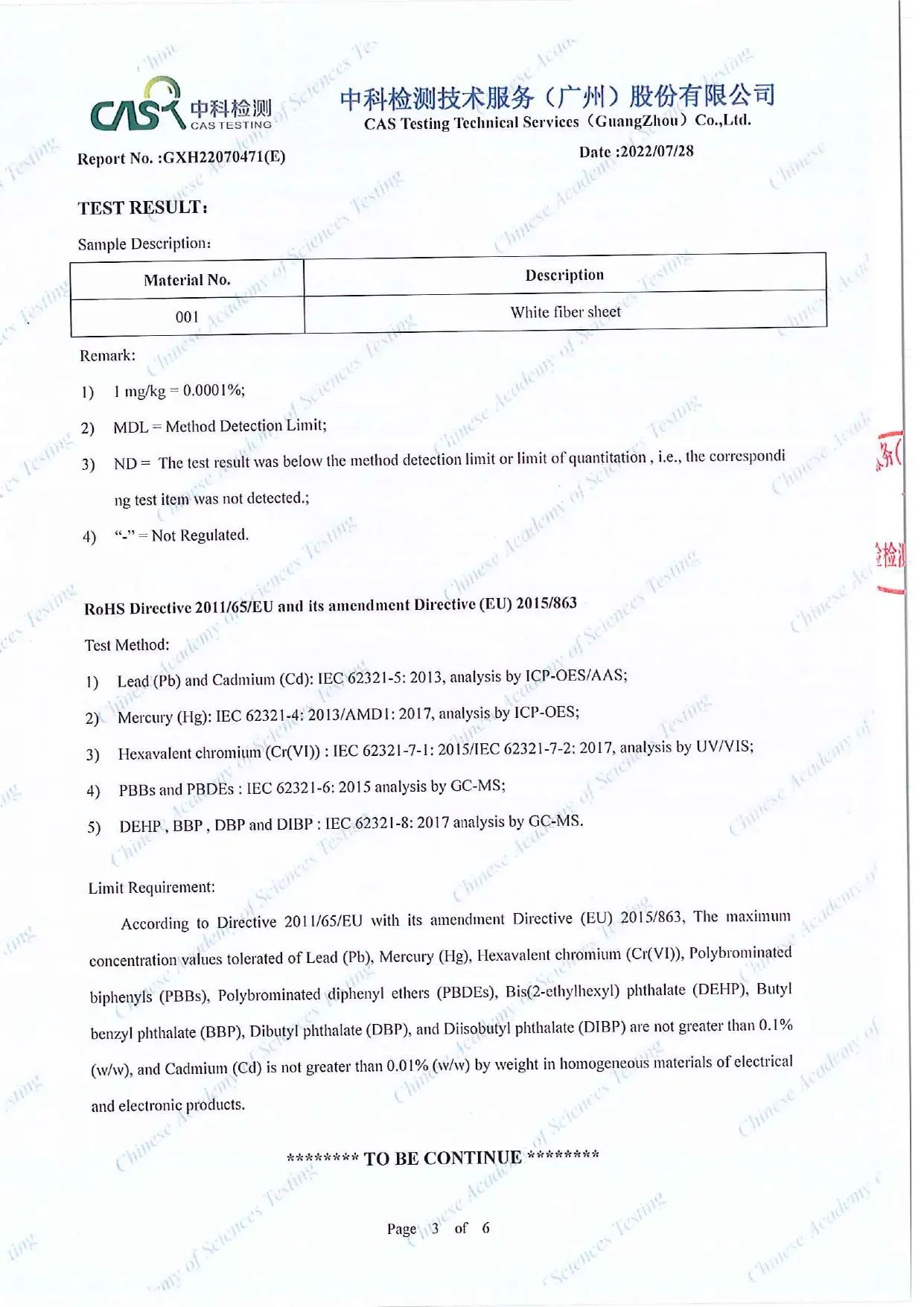

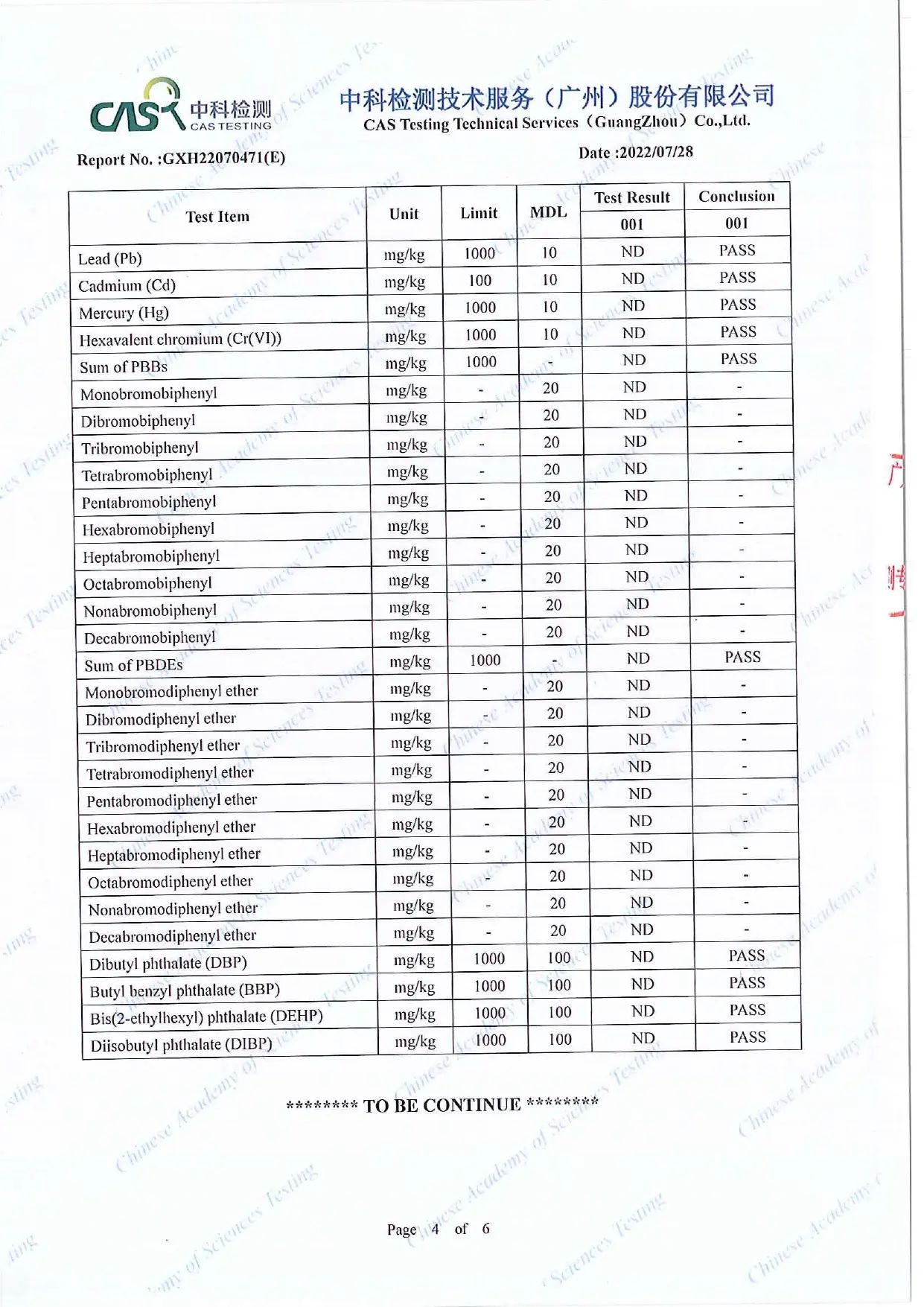

Ziurtagiria

Bideoa

DOAKO LAGIN BALDINTZAK

ONE WORLD bezeroei industriako kalitate handiko alanbre eta kable materialak eta lehen mailako zerbitzu teknikoak eskaintzeko konpromisoa hartzen du.

Interesatzen zaizun produktuaren doako lagin bat eska dezakezu, hau da, gure produktua ekoizpenerako erabiltzeko prest zaude.

Produktuaren ezaugarriak eta kalitatea egiaztatzeko eman eta partekatu nahi dituzun datu esperimentalak soilik erabiltzen ditugu, eta gero bezeroen konfiantza eta erosketa asmoa hobetzeko kalitate kontrol sistema osatuago bat ezartzen laguntzen diguzu. Beraz, lasai egon zaitez.

Eskuineko formularioa bete dezakezu doako lagin bat eskatzeko

Aplikazioaren argibideak

1. Bezeroak Nazioarteko Bidalketa Espresuko Kontua Du Edo Borondatez Ordaintzen Du Garraioa (Garraioa Eskaeran Itzul daiteke)

2. Erakunde berak produktu beraren lagin bakarra eska dezake doan, eta erakunde berak produktu desberdinen bost lagin eska ditzake doan urtebeteko epean.

3. Lagina alanbre eta kable fabrikako bezeroentzat bakarrik da, eta ekoizpen probak edo ikerketarako laborategiko langileentzat bakarrik.

LAGIN ONTZIAK

DOAKO LAGIN ESKATZEKO ORRIA

Mesedez, sartu beharrezko laginaren zehaztapenak edo deskribatu laburki proiektuaren eskakizunak, laginak gomendatuko dizkizugu.

Inprimakia bidali ondoren, betetzen duzun informazioa ONE WORLD-era bidali ahal izango da, produktuaren zehaztapenak eta helbidearen informazioa zurekin batera zehazteko prozesatu ahal izateko. Eta telefonoz ere jar gaitezke zurekin harremanetan. Mesedez, irakurri gurePribatutasun PolitikaXehetasun gehiago lortzeko.