Produkter

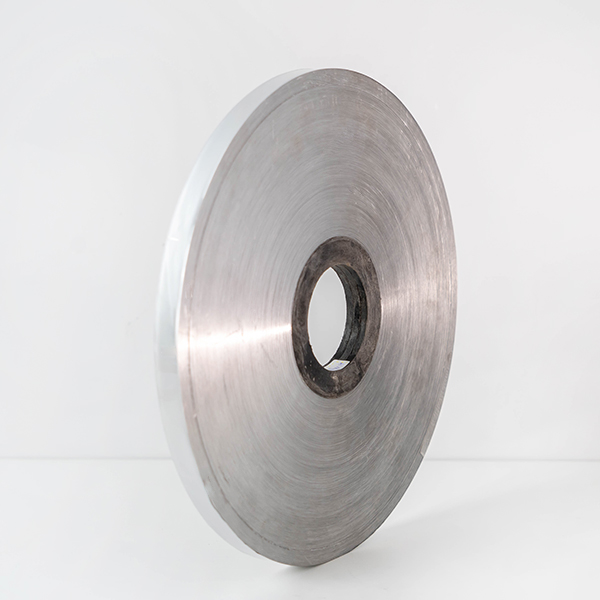

Plastbelagt aluminiumstape – Plastfolie af aluminium

Produktintroduktion

Den plastbelagte aluminiumstape er en metalkomposittape lavet af kalandrerende aluminiumstape med god duktilitet som basismateriale og lamineret med et enkelt- eller dobbeltsidet komposit polyethylen (PE) plastlag eller et copolymer plastlag.

Ved hjælp af metoden med langsgående vikling kan plastfolie af aluminium danne en kompositkappe af kablet eller det optiske kabel med den ydre ekstruderede polyethylenkappe for at fungere som vandblokerende, fugtblokerende og afskærmende. For at forbedre dens bøjningsevne kan den korrugeres for at forbedre fleksibiliteten af kabler/optiske kabler.

Vi tilbyder enkeltsidet/dobbeltsidet plastaluminiumfolie af copolymertypen og enkeltsidet/dobbeltsidet plastbelagt aluminiumstape af polyethylentypen. Den plastbelagte aluminiumstape er en metalkomposittape lavet af kalandrerende aluminiumstape med god duktilitet som basismateriale og lamineret med et enkeltsidet eller dobbeltsidet komposit polyethylen (PE) plastlag eller et copolymer plastlag.

Ved hjælp af metoden med langsgående vikling kan plastbelagt aluminiumstape danne en kompositkappe af kablet eller det optiske kabel med den ydre ekstruderede polyethylenkappe for at fungere som vandblokerende, fugtblokerende og afskærmende. For at forbedre dens bøjningsevne kan den korrugeres for at forbedre fleksibiliteten af kabler/optiske kabler.

Vi tilbyder enkeltsidet/dobbeltsidet plastaluminiumsfolie af copolymer-typen og enkeltsidet/dobbeltsidet plastbelagt aluminiumstape af polyethylen-typen.

Den plastbelagte aluminiumtape, vi leverer, har egenskaber som glat overflade, ensartethed, høj trækstyrke, høj varmeforseglingsstyrke og god kompatibilitet med fyldstoffer. Især plastbelagt aluminiumtape af copolymertypen har god ydeevne til at opnå binding ved lavere temperaturer.

Plastfolien i aluminium har to farver: naturlig og blå.

Anvendelse

Anvendes hovedsageligt i kommunikationskabler, strømkabler, udendørs optiske kabler og andre kabler, og danner en kompositkappe med den ydre kappe, der fungerer som vandblokerende, fugtblokerende og afskærmende.

Tekniske parametre

Produktspecifikationer

| Nominel totaltykkelse (mm) | Nominel aluminiumsbasetykkelse (mm) | Nominel plastlagtykkelse (mm) | |

| Enkeltsidet | Dobbeltsidet | ||

| 0,16 | 0,22 | 0,1 | 0,058 |

| 0,21 | 0,27 | 0,15 | |

| 0,26 | 0,32 | 0,2 | |

| Bemærk: Yderligere specifikationer, kontakt venligst vores salgspersonale. | |||

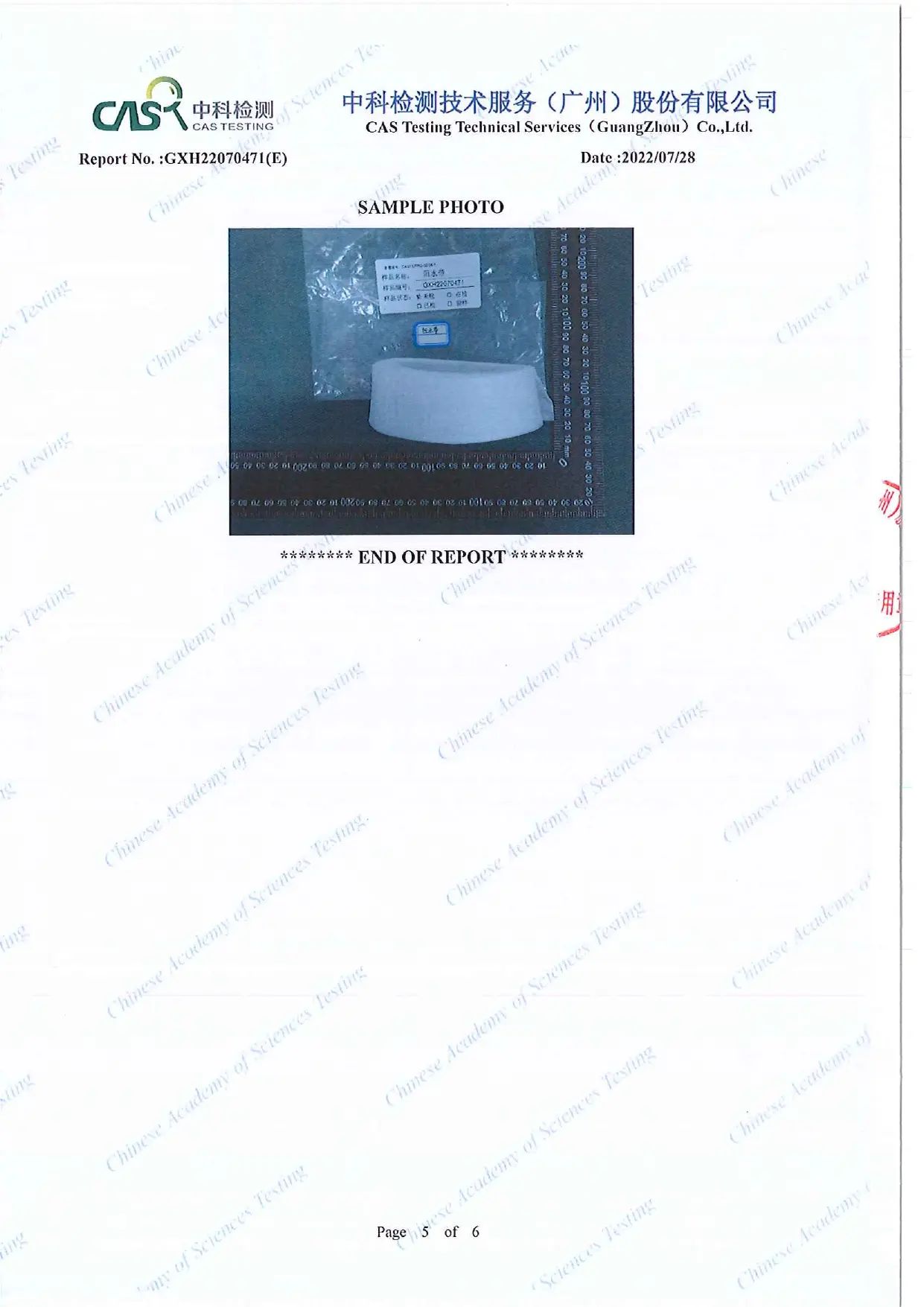

Tekniske parametre

| Punkt | Tekniske parametre | |

| Trækstyrke (MPa) | ≥65 | |

| Brudforlængelse (%) | ≥15 | |

| Skrælstyrke (N/cm) | ≥6,13 | |

| Varmeforseglingsstyrke (N/cm) | ≥17,5 | |

| Skærestyrke | Når der opstår nedbrud på aluminiumstape eller beskadigelse af varmeforseglingsområdet mellem plastlagene. | |

| Gelémodstand (68 ℃ ± 1 ℃, 168 timer) | Ingen delaminering mellem aluminiumstape og plastlag. | |

| Dielektrisk styrke | Enkeltsidet plastbelagt aluminiumstape | 1 kV dc, 1 min, ingen nedbrydning |

| Dobbeltsidet plastbelagt aluminiumstape | 2 kV dc, 1 min, ingen nedbrydning | |

Emballage

1) Plastfolie i aluminium i spolen er pakket ind i indpakningsfilm og placeret i en trækasse.

2) Plastbelagt aluminiumstape i puden pakkes ind i indpakningsfilm og stables derefter i en karton med tørremiddel og placeres derefter på pallen.

Opbevaring

1) Produktet skal opbevares på et rent, tørt og ventileret lager. Lageret skal være ventileret og køligt, undgå direkte sollys, høje temperaturer, høj luftfugtighed osv. for at forhindre produkter i at hæve, oxidere og andre problemer.

2) Produktet bør ikke stables sammen med brandfarlige produkter og bør ikke være i nærheden af ildkilder.

3) Produktet skal pakkes fuldstændigt for at undgå fugt og forurening.

4) Produktet skal beskyttes mod kraftigt tryk og anden mekanisk skade under opbevaring.

5) Produktet kan ikke opbevares i det fri, men der skal anvendes en presenning, når det skal opbevares i det fri i kort tid.

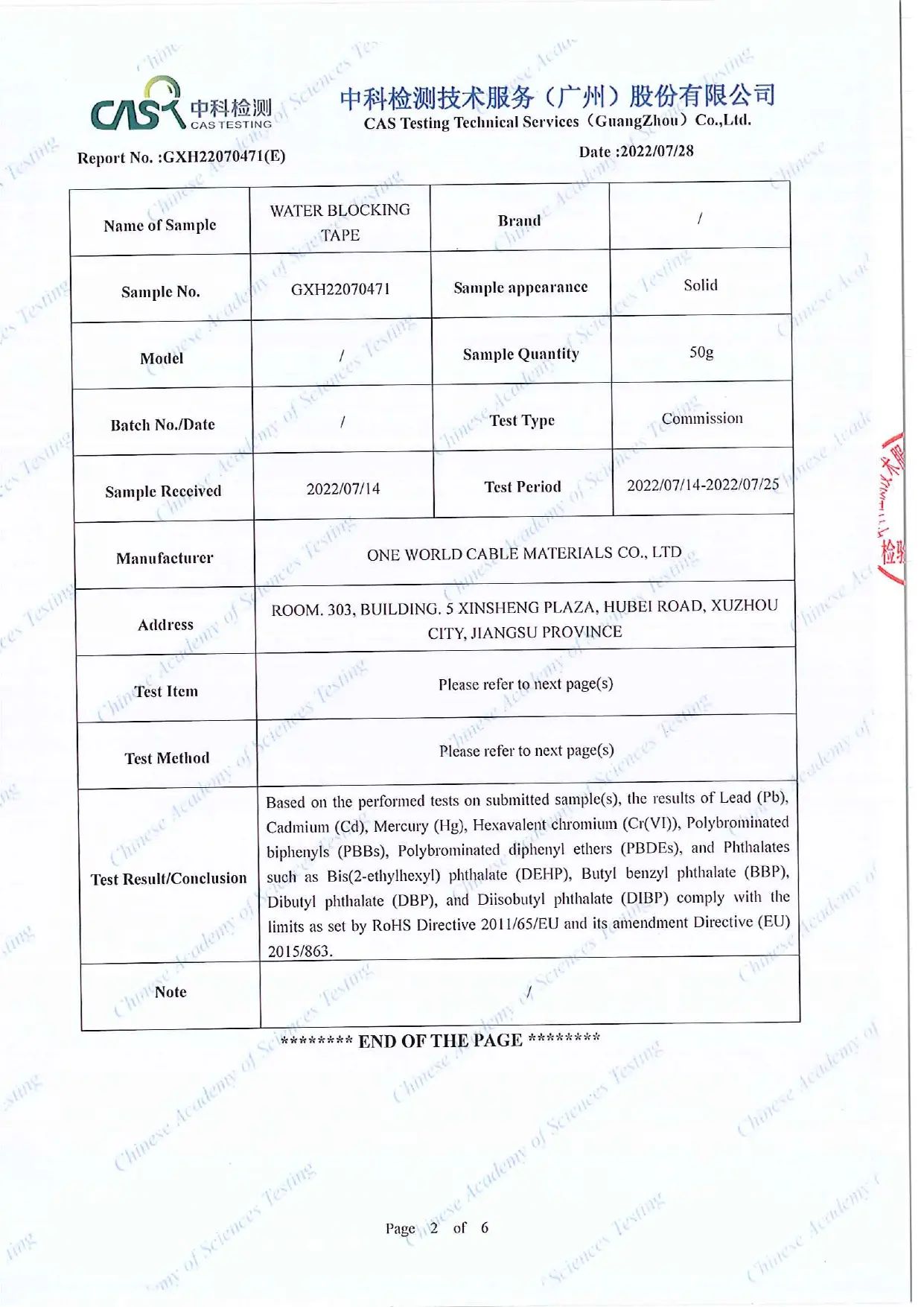

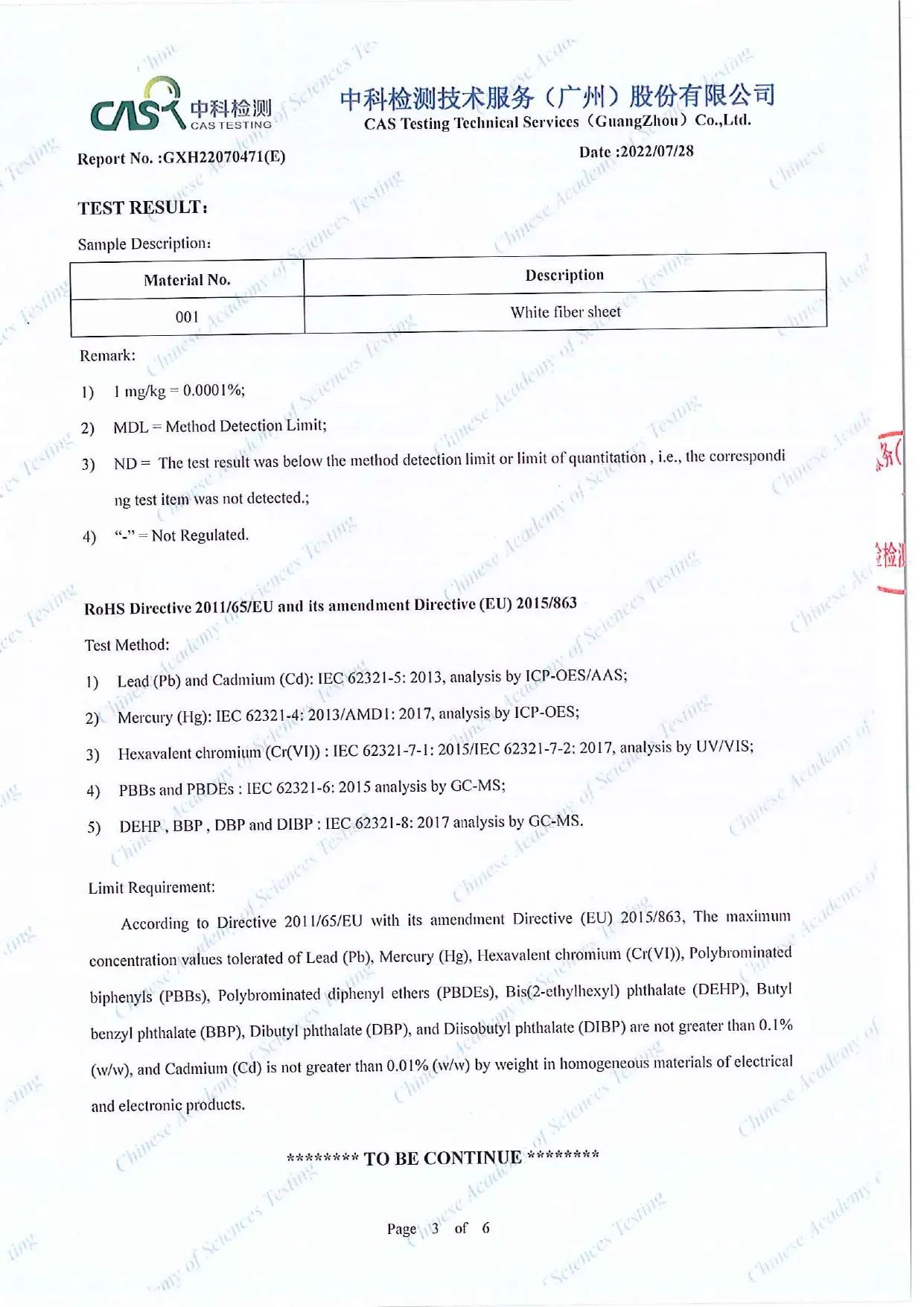

Certificering

Video

GRATIS PRØVEVILKÅR

ONE WORLD er forpligtet til at levere brancheførende lednings- og kabelmaterialer af høj kvalitet samt førsteklasses tekniske tjenester.

Du kan anmode om en gratis prøve af det produkt, du er interesseret i, hvilket betyder, at du er villig til at bruge vores produkt til produktion.

Vi bruger kun de eksperimentelle data, du er villig til at give feedback og dele, som verifikation af produktegenskaber og kvalitet, og hjælper os derefter med at etablere et mere komplet kvalitetskontrolsystem for at forbedre kundernes tillid og købsintention. Du kan derfor være sikker på, at vi er her.

Du kan udfylde formularen til højre for at anmode om en gratis prøve

Anvendelsesvejledning

1. Kunden har en international ekspresleveringskonto og betaler frivilligt fragten (fragten kan returneres i ordren)

2. Den samme institution kan kun ansøge om én gratis prøve af det samme produkt, og den samme institution kan ansøge om op til fem prøver af forskellige produkter gratis inden for et år.

3. Prøven er kun til kunder på lednings- og kabelfabrikker og kun til laboratoriepersonale til produktionstestning eller forskning.

PRØVEEMBALLAGE

GRATIS PRØVEFORMULAR

Indtast venligst de nødvendige prøvespecifikationer, eller beskriv kort projektets krav. Vi vil anbefale prøver til dig.

Efter du har indsendt formularen, kan de oplysninger, du udfylder, blive sendt til ONE WORLD-baggrunden til videre behandling for at fastlægge produktspecifikationer og adresseoplysninger med dig. Vi kan også kontakte dig telefonisk. Læs venligst voresPrivatlivspolitikFor flere detaljer.