Since 2023, ONE WORLD has been working closely with an Israeli optical cable manufacturer. Over the past two years, what began as a single-product purchase has evolved into a diversified and in-depth strategic partnership. The two sides have collaborated extensively in the fields of power cables and fiber optic communication materials, building an efficient and stable raw material supply chain—witnessing mutual growth and trust along the way.

From First Contact to Long-Term Trust: It All Starts with Quality

Two years ago, the customer was searching for a reliable PBT jacket material supplier. After exploring the ONE WORLD website, they gained an in-depth understanding of our technical capabilities and product portfolio in fiber optic cable materials. Through communication and sample testing, the customer recognized the outstanding performance of our PBT in tensile strength, weather resistance, processing stability, and color consistency, leading to an initial trial order of 1 ton.

During actual use, the PBT performed excellently, fully meeting the requirements for fiber cable jackets in complex environments. ONE WORLD's professional service in delivery timelines, logistics coordination, and after-sales support further strengthened the customer's confidence.

Upgraded Cooperation: From PBT to HDPE and Integrated Multi-Material Procurement

Following a successful first round of cooperation, the customer quickly expanded their PBT procurement volume and shifted more sourcing needs to ONE WORLD. This included: High-wear, anti-aging HDPE jacket material for communication cable sheathing, Modified PP filler compounds to improve structural stability and uniform filling,

As well as FRP, water-blocking yarn, and Mylar tape, enabling integrated sourcing for all cable materials.

This centralized procurement model significantly reduced communication and logistics costs for the customer, while showcasing ONE WORLD's capabilities in providing one-stop cable material solutions.

On-Site Visits: Seeing is Believing

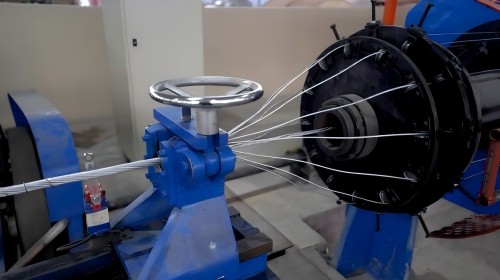

This year, the customer visited China and conducted an on-site inspection of ONE WORLD's galvanized steel strand production facility. From raw material selection, hot-dip galvanization processes, and stranding control to tensile testing and zinc adhesion checks, they closely observed the entire quality control process.

Test results on-site confirmed the product's reliability in key areas such as corrosion resistance, tensile strength, zinc coating uniformity, and stable stranding tension. The customer remarked that ONE WORLD not only has a strong manufacturing foundation and a professional engineering team, but also offers reliable delivery and after-sales service—making it a trusted long-term partner.

Full Product Range Support: Building a High-Compatibility Raw Material System

As a company dedicated to the R&D and manufacturing of power and fiber optic cable materials, ONE WORLD remains committed to the service philosophy of “high quality, high compatibility, fast delivery.” We continue to provide global customers with a wide range of stable-performance raw materials, including:

Fiber Optic Cable Materials: PBT, FRP, aramid yarn, water-blocking tape, jelly filling gel, etc., widely used in cable filling, reinforcement, and protective layers.

Power Cable Materials: Mica tape, Mylar tape, Aluminum foil mylar tape, Copper tape, Water-blocking tape, Galvanized steel tape, Galvanized steel strand, PP filler rope, Plastic coated steel tape, etc., to enhance cable strength, fire resistance, and durability.

Plastic Extrusion Materials: PVC, PE, XLPE, LSZH, etc., for insulation and sheathing applications in wires and cables, meeting various performance and environmental standards.

With a stable and efficient supply chain and strict quality control, ONE WORLD ensures raw materials with strong traceability, on-time delivery, and minimal quality fluctuation, fully supporting the efficient production of optical, communication, control, mining, and specialty cables.

Looking Ahead: Technology-Driven, Co-Creating Value

Over the past two years, our cooperation has laid a strong foundation of trust and established a solid collaborative mechanism. Looking ahead, ONE WORLD will continue to be customer-oriented, leveraging a robust product system and optimized supply chain services to expand global partnerships—driving innovation and green development in the cable industry.

We welcome more cable manufacturers from around the world to join the ONE WORLD network and work with us to build a raw material supply ecosystem that is more efficient, higher standard, and higher quality.

Post time: Apr-30-2025