ONE WORLD exported a batch of aluminum foil polyethylene tape, the tape is mainly used to prevent signal leakage during the transmission of signals in coaxial cables, the aluminum foil plays an emitting and refracting role and has a good shielding effect. The self-adhesive copolymer side is 100% longitudinally bonded to the foamed polyethylene insulator.

We would like to share with you the quality inspection work that we do for appearance, size, color, performance, packaging, etc. during the production process and before shipment in accordance with customer requirements and industry standards.

1.Appearance Confirmation

(1)The aluminum foil polyethylene tape should be continuously and tightly laminated, and its surface should be smooth, flat, uniform, free of impurities, wrinkles, spots, and other mechanical damage.

(2) Aluminum foil polyethylene tape should be wound tightly and should not collapse when used vertically.

(3) The unslitted aluminum foil polyethylene tape is allowed to have 2~5mm plastic film protection on the side, and the side should be flat, without defects such as rolled edge, gap and burr, and the misalignment between layers is less than 1mm.

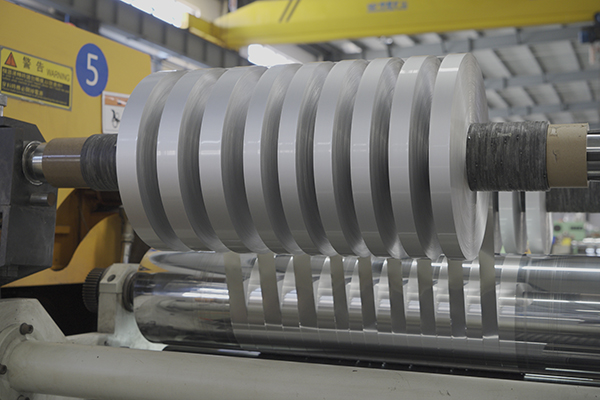

(4) The end face of the slit aluminum foil polyethylene tape should be flat, with an unevenness of not more than 0.5mm, and should be free of rolled edges, gaps, knife marks, burrs and other mechanical damage. When the aluminum foil polyethylene tape is put on the tape, it is not self-adhesive, and the edge should be free of obvious wavy shape (commonly known as ruffled edge).

2.Size Confirmation

(1) The width, total thickness, thickness of aluminum foil, thickness of polyethylene, and inner and outer diameter of the wrapping tape of aluminum foil and polyethylene meet customer requirements.

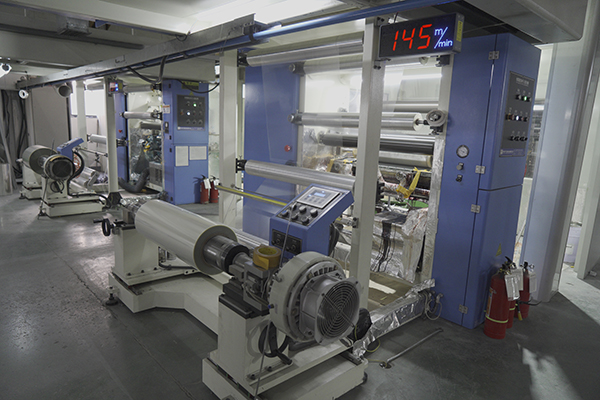

Aluminum Foil Polyethylene Tape1

Size Test of Aluminum Foil Polyethylene Tape

(2) No joint is allowed in the same tray of metal-plastic composite foil that has been slit and the same roll of metal-plastic composite foil that has not been slit.

3. Color Confirmation

Aluminum foil polyethylene tape color should be consistent with customer requirements.

4. Performance Confirmation

The tensile strength and elongation at break of the aluminum foil polyethylene tape were tested, and the test results met industry standards and customer requirements.

5. Packaging Confirmation

(1) The aluminum foil polyethylene tape should be tightly wound on the tube core made of plastic, the length of the core of the slit aluminum foil polyethylene tape should be the same as the width of the composite foil, the end of the tube core protruding from the aluminum foil polyethylene tape should be less than 1mm, and the end of the aluminum foil polyethylene tape should be fixed firmly to prevent loosening.

(2) The slit aluminum foil polyethylene tape should be placed flat and several trays form a package.

These requirements are our basic requirements for aluminum foil polyethylene tape before leaving the factory, we will ensure that the quality of each batch of products meet customer requirements and industry standards, to provide each customer with quality products and services, welcome to contact us at any time.

Post time: Jun-22-2022