As power systems rapidly evolve toward higher voltage and larger capacity, the demand for advanced cable materials continues to grow. ONE WORLD, a professional supplier specializing in cable raw materials, is committed to technology innovation and stable production of high-performance cross-linked polyethylene (XLPE) insulation materials. Our XLPE insulation materials serve medium and high voltage power cables, communication cables, and special cable manufacturers, empowering industry upgrades in product quality and sustainable development.

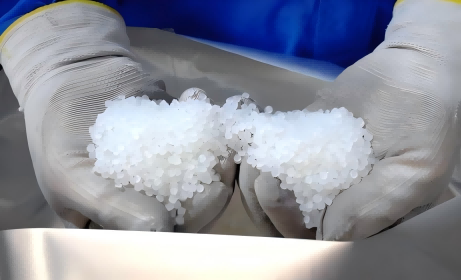

XLPE insulation material remains one of the most mature and widely adopted extrusion materials in the cable manufacturing industry. It offers excellent electrical insulation, superior thermal stability, and strong mechanical properties. Moreover, its mature processing technology, ease of operation, and cost-effectiveness make it the preferred choice for power cables, communication cables, control cables, and other medium to high voltage cable applications. Leveraging a mature two-step silane cross-linking process and optimized formulation technology, ONE WORLD operates three A-compound and one B-compound production lines, with an annual capacity of 35,000 tons, ensuring a reliable and large-scale supply of XLPE cable insulation materials.

Our XLPE insulation materials are designed to withstand continuous operation at 90°C and short-term temperatures up to 250°C (which refers to short-term thermal aging resistance, not continuous use). Even under harsh conditions involving high temperatures and pressures, they maintain dimensional stability and electrical safety. To ensure consistent extrusion quality, we strictly control gel content, moisture, and impurities, minimizing defects such as bubbles and shrinkage, which enhances the stability, yield, and uniformity of cable products.

ONE WORLD enforces a comprehensive quality management system throughout production. Raw materials undergo a triple-check process by logistics, quality control, and production teams to prevent moisture ingress. Precise manual feeding combined with real-time online monitoring maintains strict control over impurity and moisture content. An 8-minute intensive mixing stage ensures homogeneity before vacuum metering and packaging using aluminum-plastic vacuum bags, effectively protecting products from moisture during transport and storage.

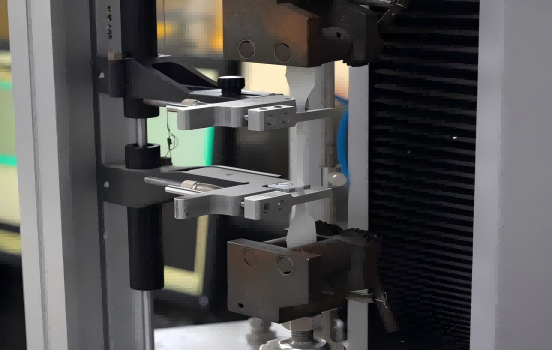

Each batch of XLPE insulation material passes rigorous tests, including hot set, extrusion slice analysis, tensile strength, and elongation at break, guaranteeing compliance with electrical and physical standards. This ensures our XLPE insulation materials consistently meet the stringent requirements of cable manufacturers seeking high-performance raw materials.

To cater to diverse customer needs, ONE WORLD offers customized XLPE materials in various grades and colors, compatible with different extrusion machinery and process parameters. Our products are widely used across power cables, optical cables, control cables, and data cables, supporting a broad spectrum of cable manufacturing applications.

In addition to product supply, our experienced technical service team provides end-to-end support—from raw material selection and formula optimization to extrusion process guidance—helping customers overcome challenges in both trial runs and mass production. We also provide free sample applications, encouraging potential customers to validate product compatibility and accelerate project timelines.

Looking forward, ONE WORLD will continue to focus on innovation in XLPE insulation materials, emphasizing performance enhancement and eco-friendly applications. Partnering globally, we strive to build a high-quality, safe, and sustainable cable materials supply chain that supports the future of power and communication infrastructure worldwide.

Post time: Jul-23-2025